Morgan-Press G-125T Injection Molding Machine

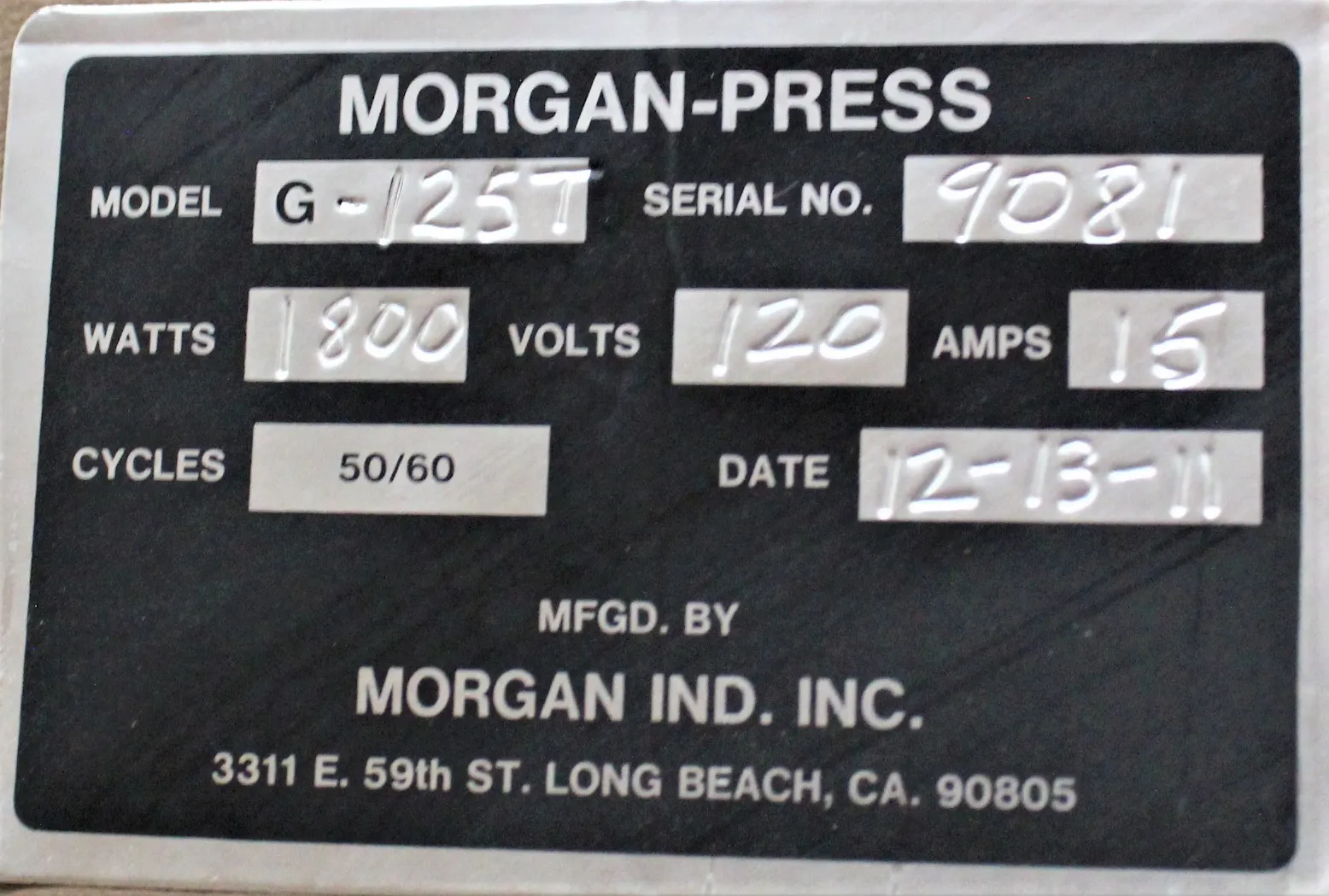

- Make Morgan-Press

- Hertz 60Hz US

- Model G-125T

- Serial 9081

- Weight 170.0 Lb

- Voltage 120V

- Includes Power cord included |

- Warranty 30-Day Warranty, 100% Parts and Labor

- Dimensions 21.0in x 25.0in x 68.0in

- Shipping Type FedEx Ground

- Item Condition Excellent

- Manufacturing Date Does Not Apply

Product Information

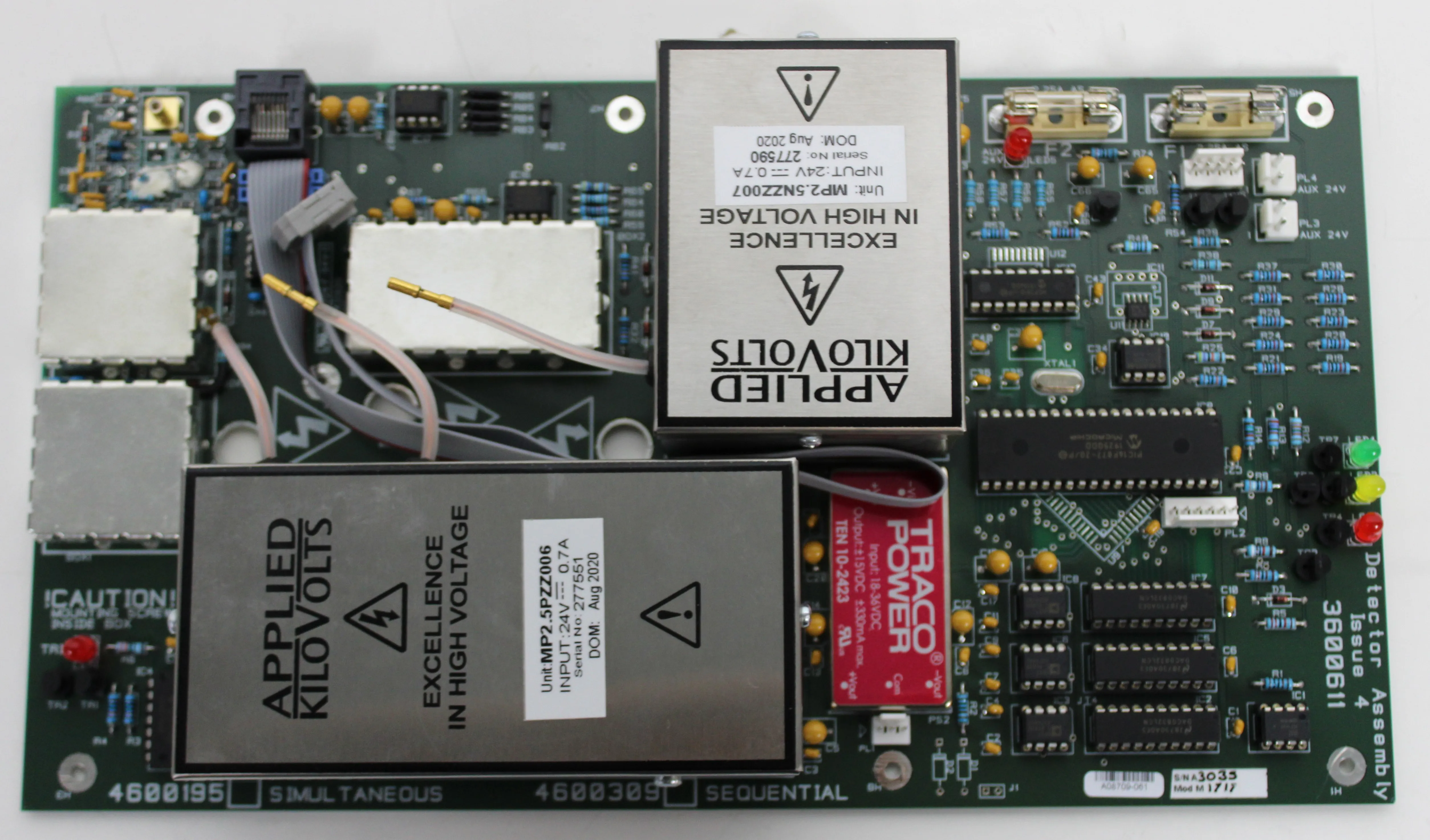

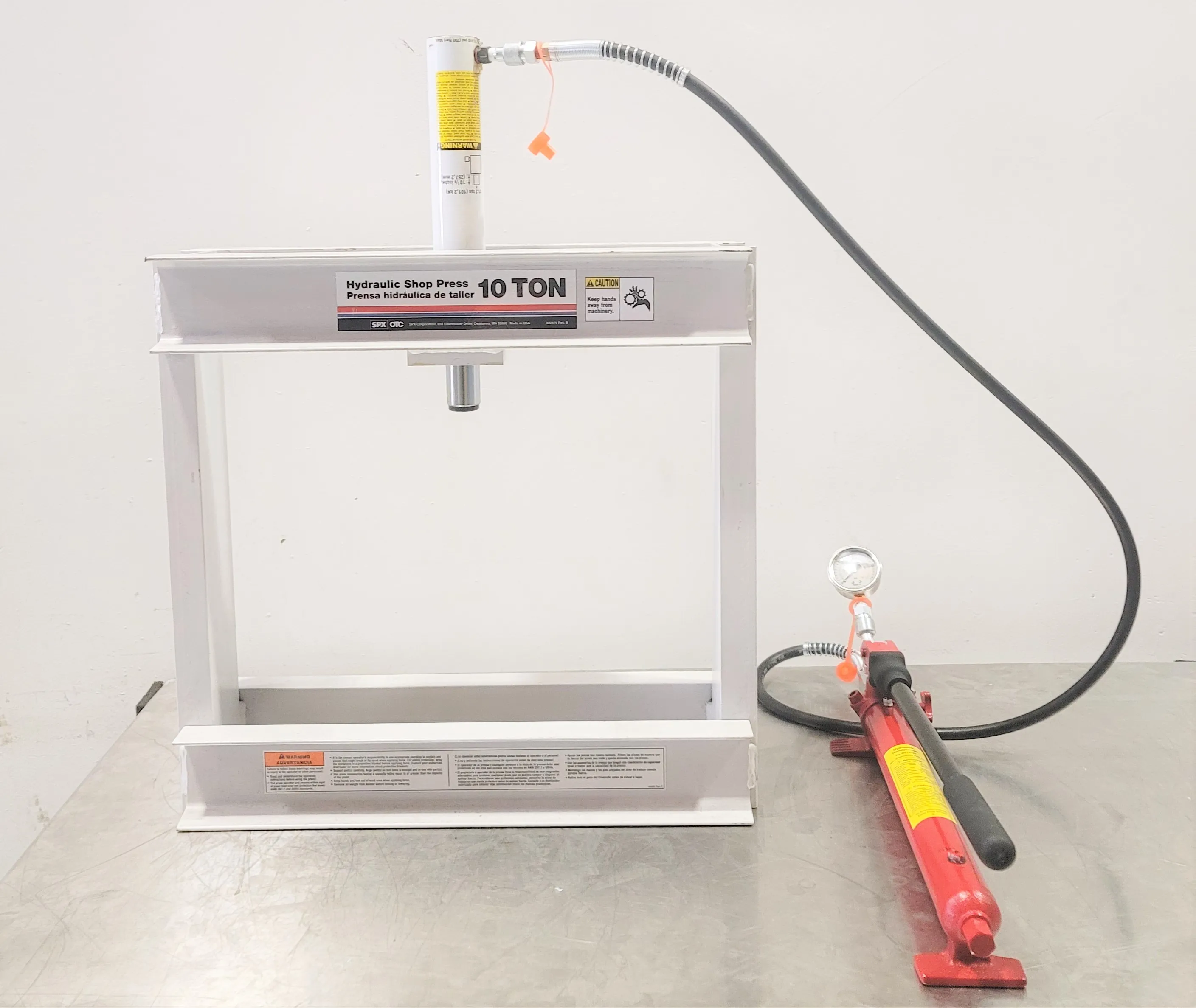

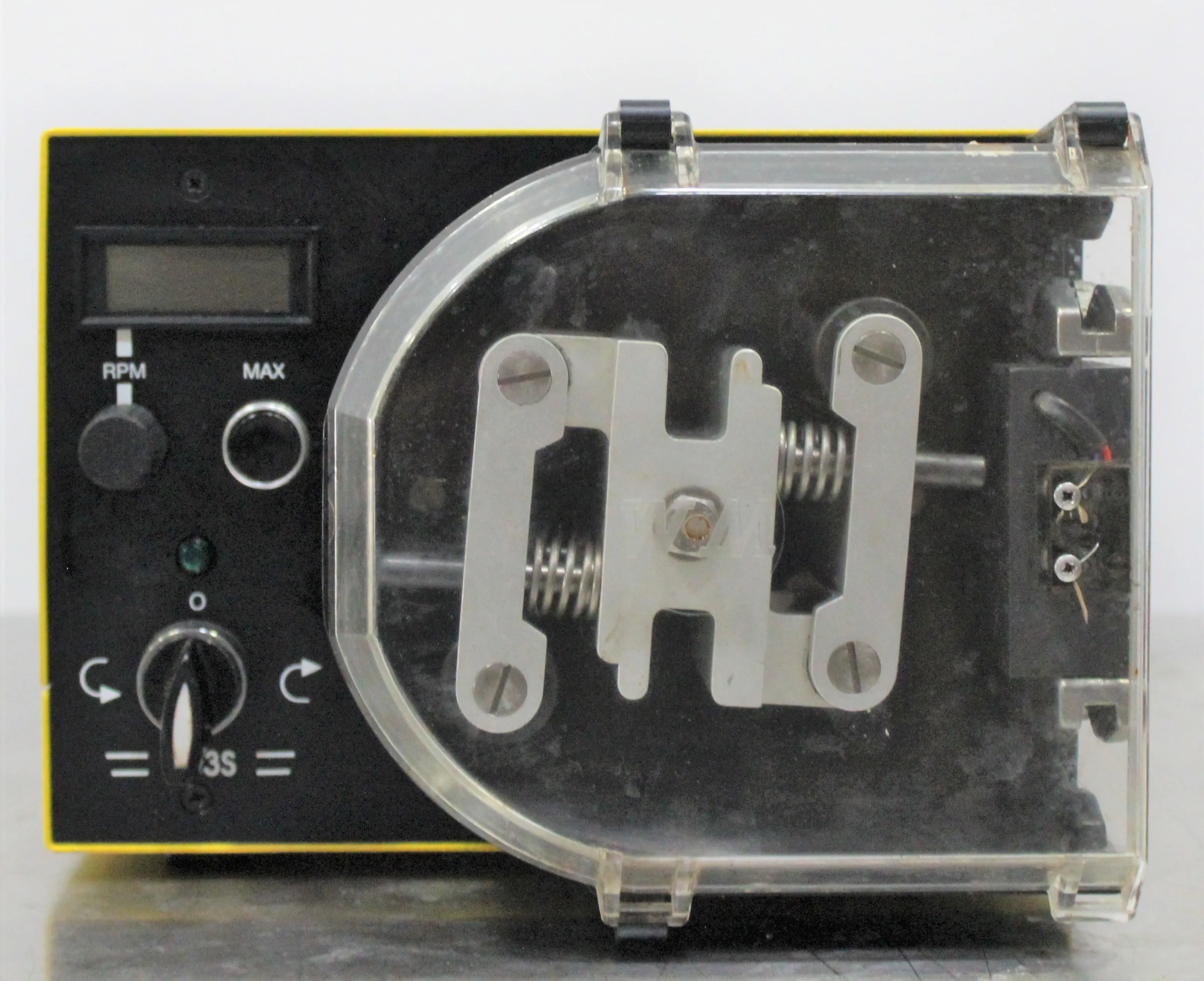

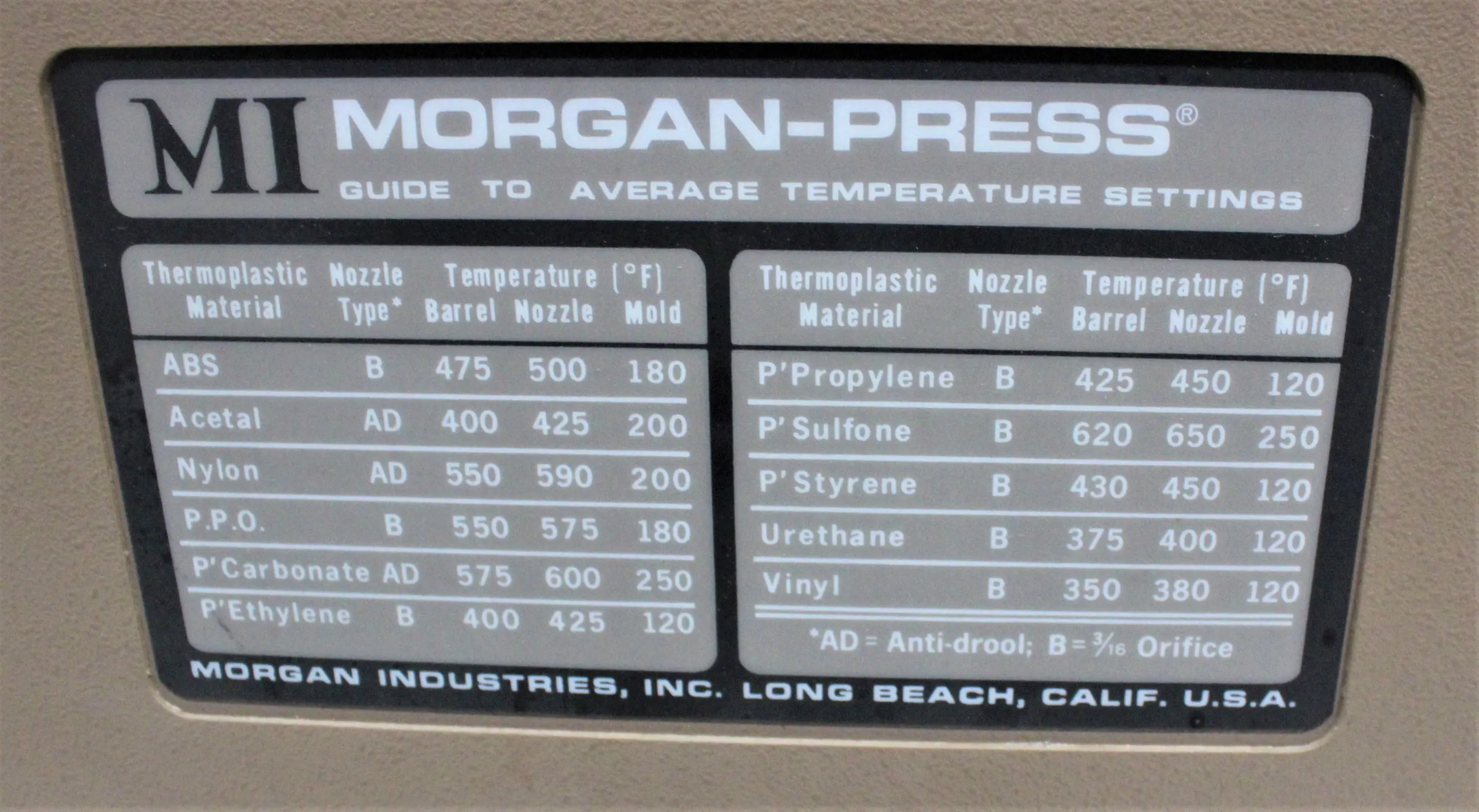

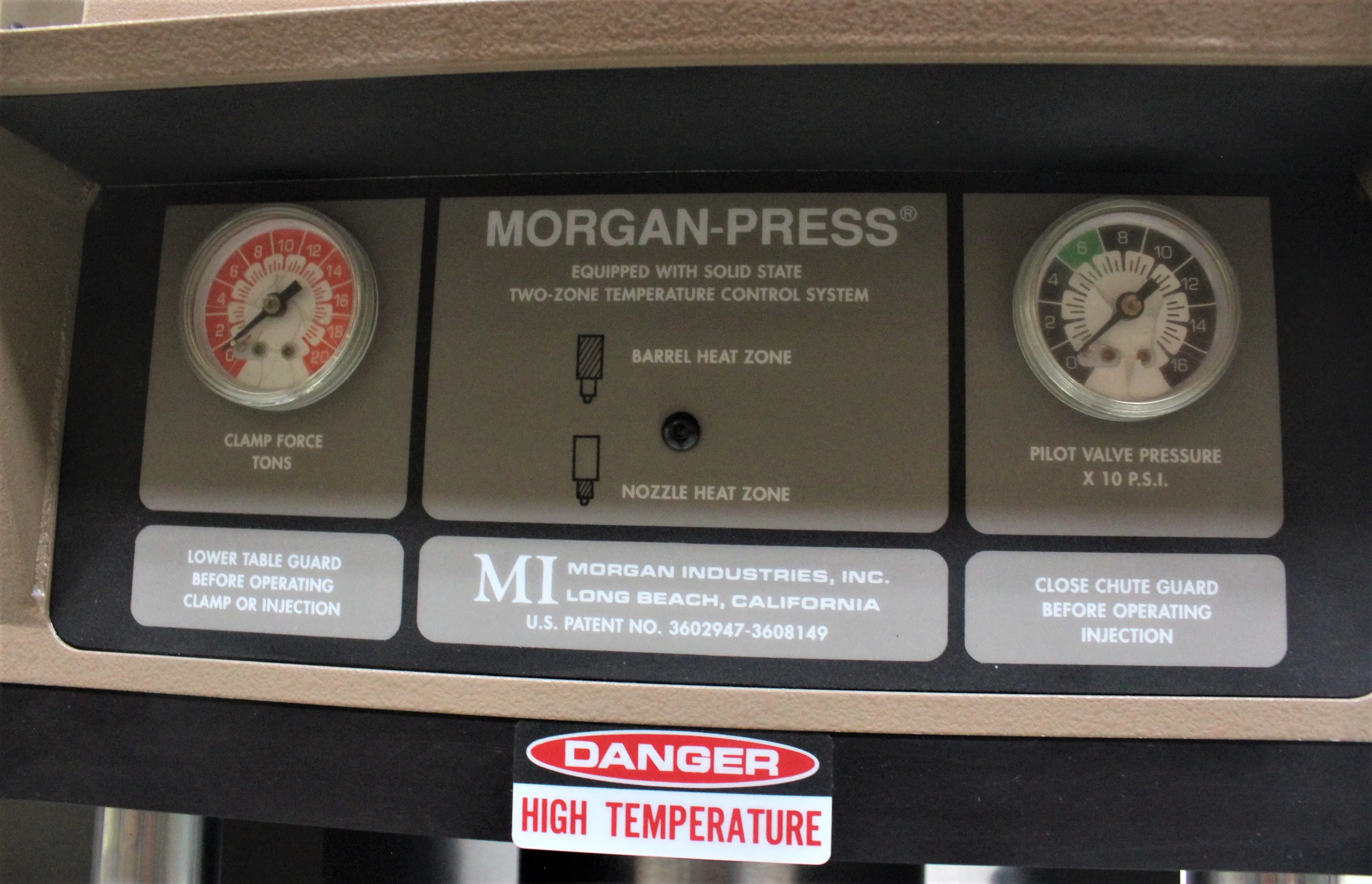

As an intelligent laboratory scientist, let's delve into the versatile Morgan-Press G-125T injection molding machine. This unique and economical machine was designed to cater to the cost-effective production of plastic parts, making it ideal for model shops, medical device manufacturers, R&D labs, and other plastic injection molding applications requiring short-run production. With features such as solid state temperature controllers, injection speed control, and a generous mold plan area of 8" x 11", it's a valuable asset for rapid prototyping and low-volume production needs. Whether it's precision ground chrome-plated stanchion rods or the need for 120V AC electrical hook-up, this efficient machine promises practicality, economy, and reliability. The Morgan-Press G-125T is a perfect amalgamation of practical design and advanced technology, offering industries the most sought-after short-run injection molding solutions.

Key Features- Versatile and economical injection molding machine

- Solid state temperature controllers with a digital set point and readout

- Injection speed control for adjusting cavity fill rates

- Heavy-duty cast aluminum construction

- Generous 8" x 11" mold plan area

- 7.5 cu. in. (5 oz.) max. single shot

- 20-ton max. clamping force (toggle)

- 9,000 psi max. injection pressure

- 0-800F (0-430C) temperature control range

Metric: 76.6 kg

Imperial: 168.7 lbs

Metric: 53.34 cm x 43.18 cm x 172.72 cm

Imperial: 21 in x 17 in x 68 in

847710

Harmonized Code DetailsInjection-moulding machines

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”