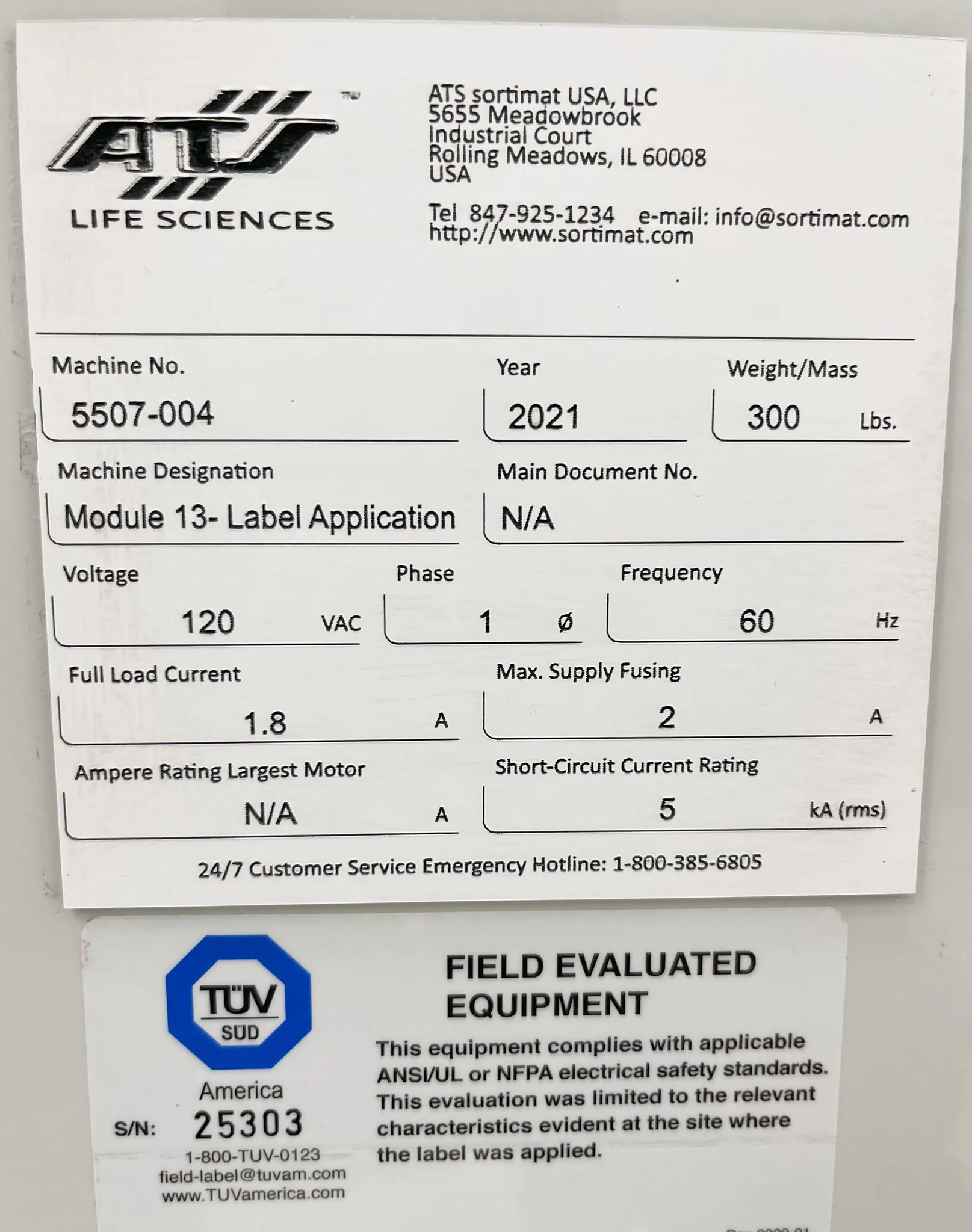

ATS Life Sciences Model 13-Label Applications - Nautilus Systems PL100I ER

Same item available with different options / conditions

- Make ATS Life Sciences

- Hertz 50Hz/60Hz

- Model 13- Lable Application

- Serial 5507-004

- Weight 260.0 Lb

- Voltage 120V

- Includes Service records included |

- Warranty 30-Day Warranty On Part

- Dimensions 85.0in x 16.0in x 60.0in

- Shipping Type Freight

- Item Condition Good

- Manufacturing Date Does Not Apply

Product Information

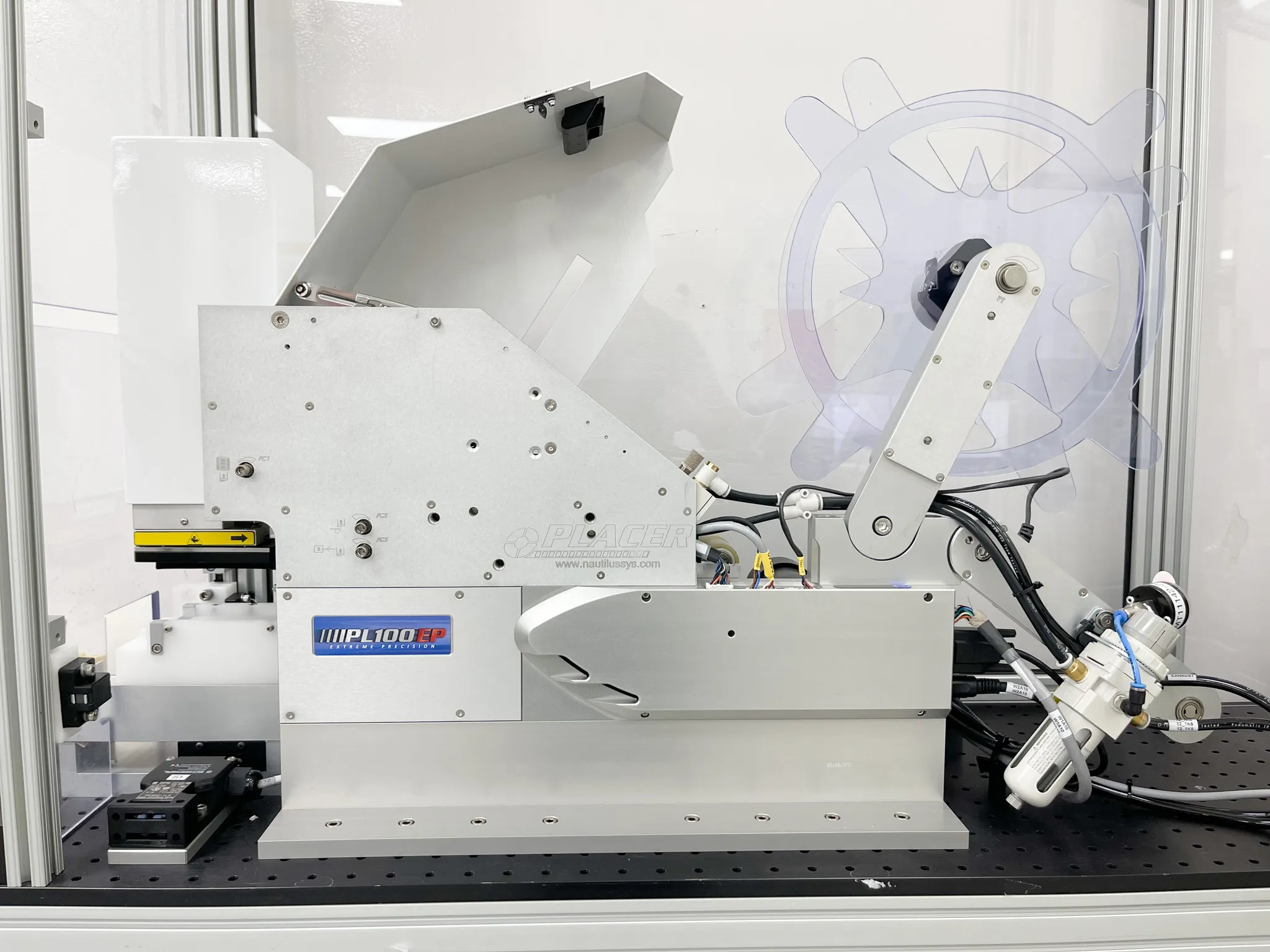

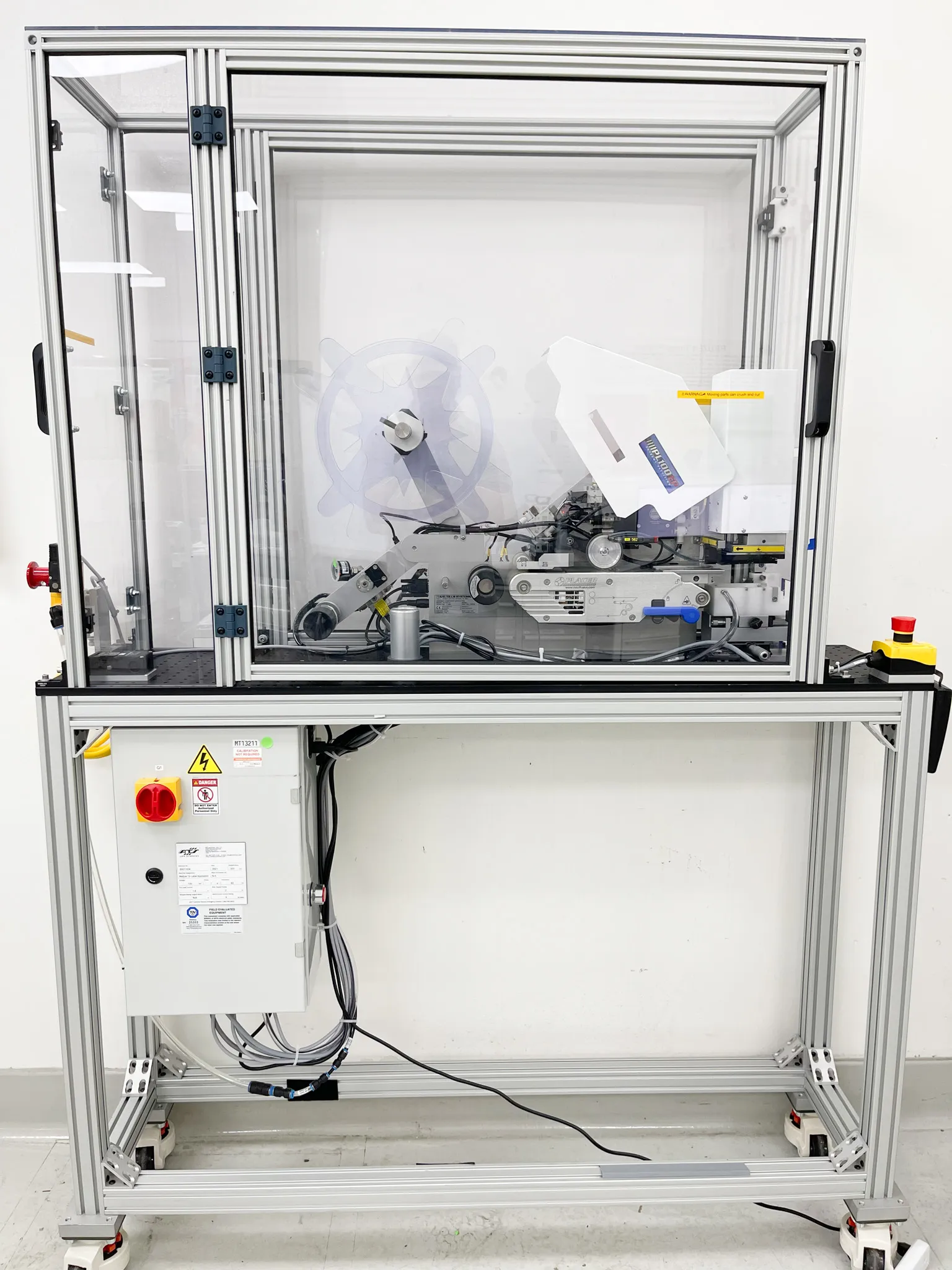

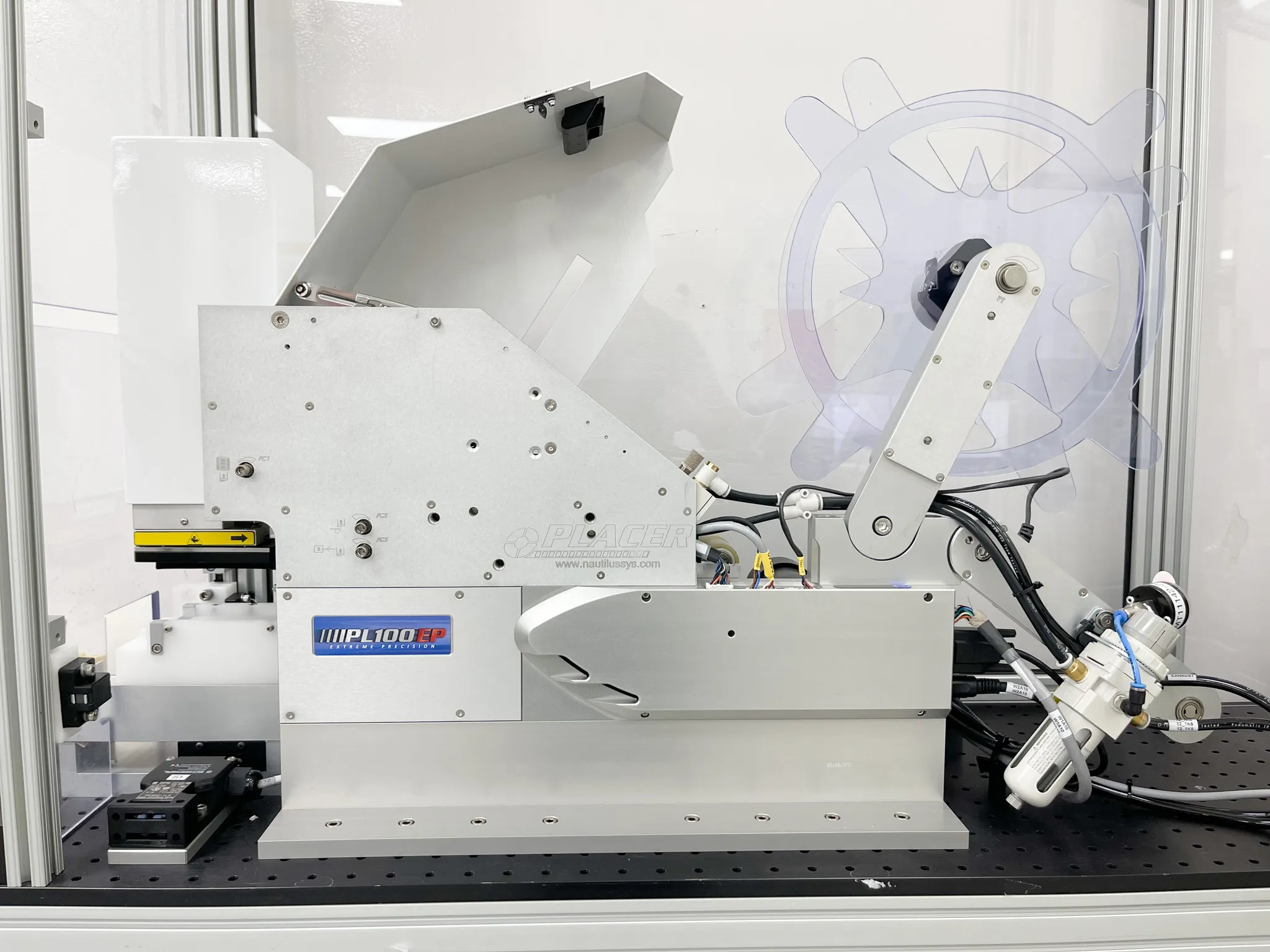

ATS LIFE SCIENCES MODEL 13-LABEL APPLICATIONS Nautilus Systems PL100I ER Quantity: 4x Pl100EPR (Model 13-label Application) The All-Electric PL100EPr provides a highly accurate and reliable feed and peel system of virtually any shape of die-cut adhesive component. No pneumatics simplifies setup and maintenance. It provides capacity for components up to 100 x 100mm in size. The EP Package provides maximum accuracy with measured results as good as +/- 0.035mm. The EP Package incorporates a closed-loop feedback system to monitor travel of the material and verify the correct feed location at an increased resolution as compared to the standard PL100r. The PL100EPr is configured specifically for integration into automated assembly solutions. It includes all of the hardware necessary for operation including a pneumatic precision-guided Tamp actuator assembly, a Payoff assembly, and a powered Takeup (rewind) assembly. Custom Component Tooling (CCT) is the tooling package configured specifically for your die-cut component. The CCT items consist of a Vacuum Chuck, Blade Guide Pad, and Liner Guide Roller. All CCT items are customized per the specifications of your material and are configured for rapid changeover which means no tools are required to remove or replace the tooling. Typical Applications: 1. Automated Pharmaceutical Assembly Lines, 2. Adhesive Component Manufacturing, 3. Integrated Labeling Systems Current Condition: Used - G (Good) The PL100EPr offers a precise and efficient label application process, catering to the needs of automated pharmaceutical assembly lines, adhesive component manufacturing, and integrated labeling systems. The model's closed-loop feedback system ensures maximum accuracy for consistent and reliable performance. It is designed to facilitate rapid changeover and seamless integration, making it an essential component in modern automated assembly solutions.

Key Features- Highly accurate and reliable feed and peel system

- Capacity for components up to 100 x 100mm

- Closed-loop feedback system for maximum accuracy

- Configured specifically for integration into automated assembly solutions

- Custom Component Tooling for rapid changeover

- Accurate Feed and Peel System: Yes

- Maximum Component Size: 100 x 100mm

- Accuracy: +/- 0.035mm

- Automation Integration: Yes

- Custom Component Tooling: Included

Metric: 117.93 kg

Imperial: 260 lb

Metric: 80 cm x 14 cm x 58 cm

Imperial: 31.5 in x 5.5 in x 22.8 in

842230

Harmonized Code DetailsFound under Harmonized System Code 842230 for Machinery and Equipment for the Pharmaceutical and Chemical Industries. This code best identifies the label application system's function and intended use within the pharmaceutical manufacturing industry.

Same item available with different options / conditions.

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”