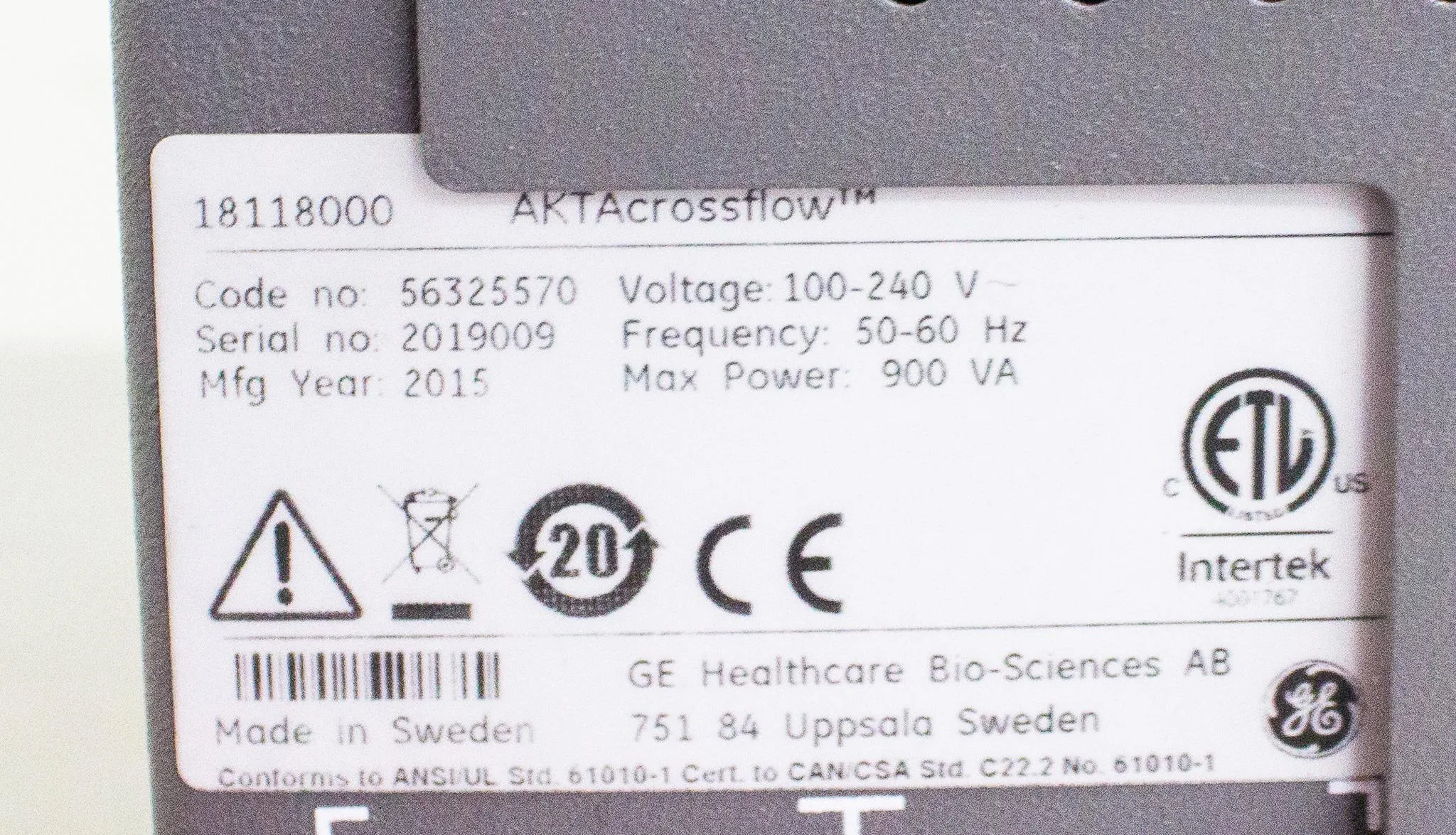

GE AKTAcrossflow Tangential Flow Filtration System 18118000

- Make GE

- Hertz 50Hz/60Hz

- Model AKTAcrossflow

- Serial 2019009

- Weight 180.0 Lb

- Voltage 120V/220V

- Includes Power cord included |

- Warranty 30-Day Warranty On Part

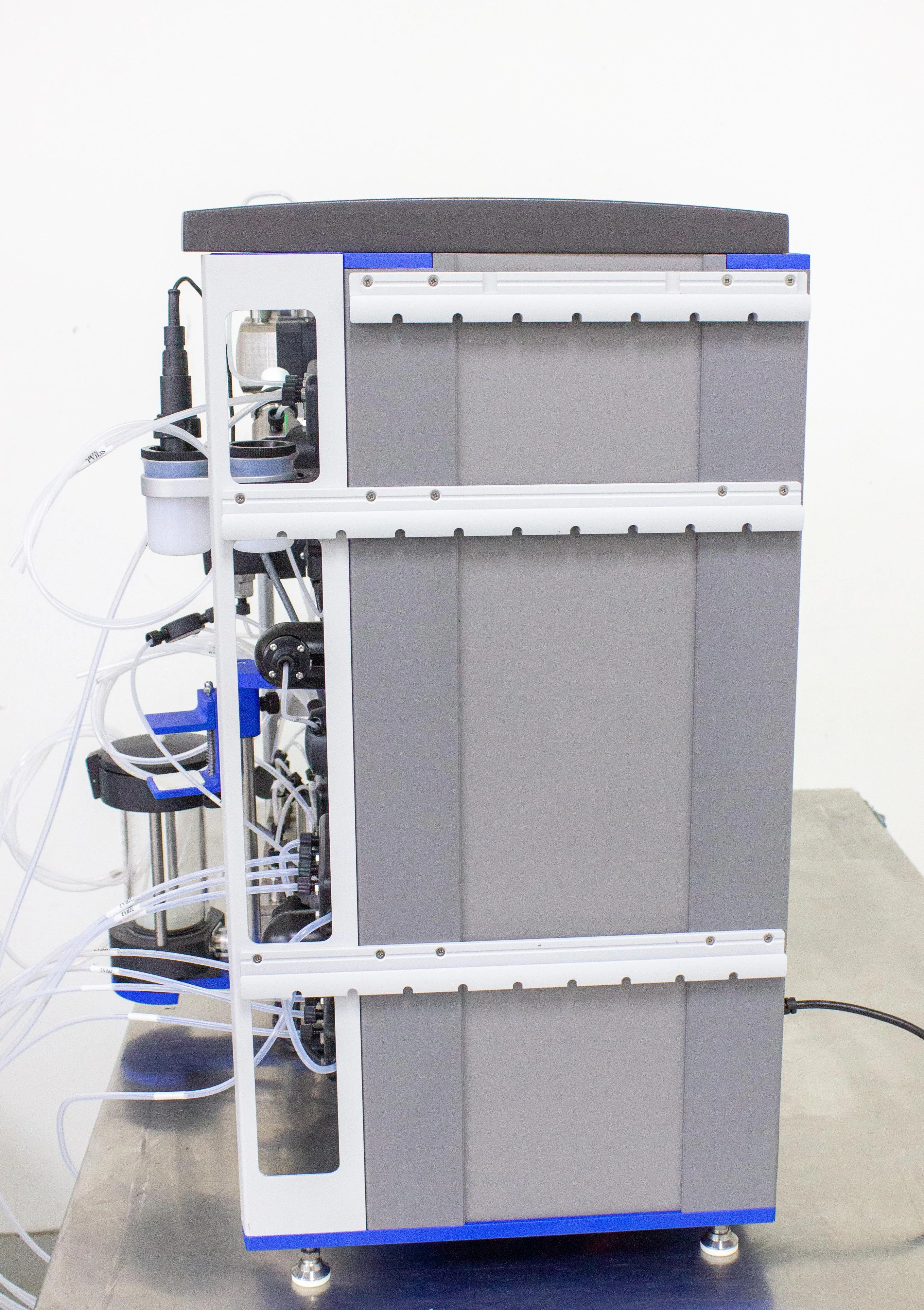

- Dimensions 22.0in x 35.0in x 32.0in

- Shipping Type Freight

- Item Condition Good

- Manufacturing Date 2015-01-01

Product Information

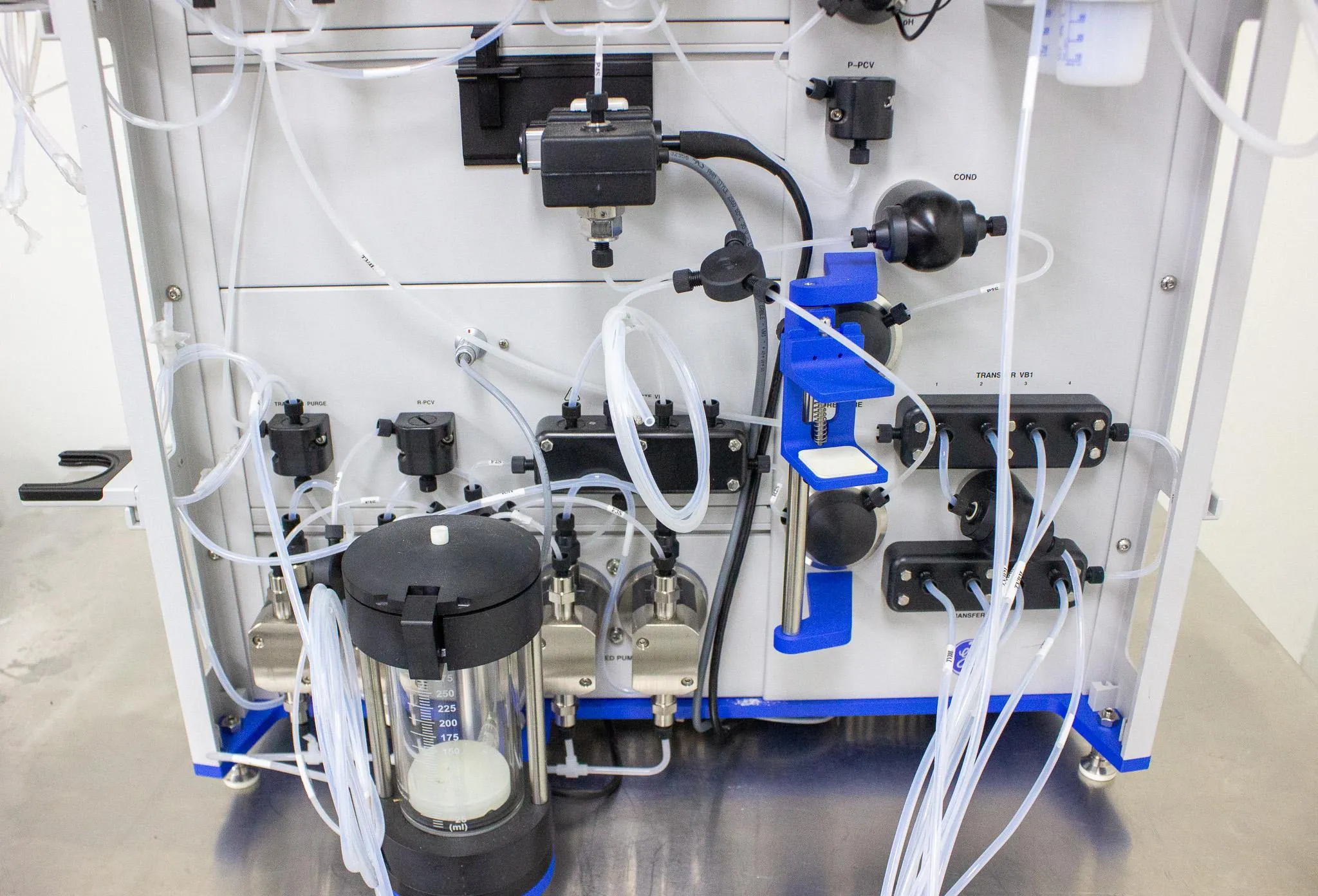

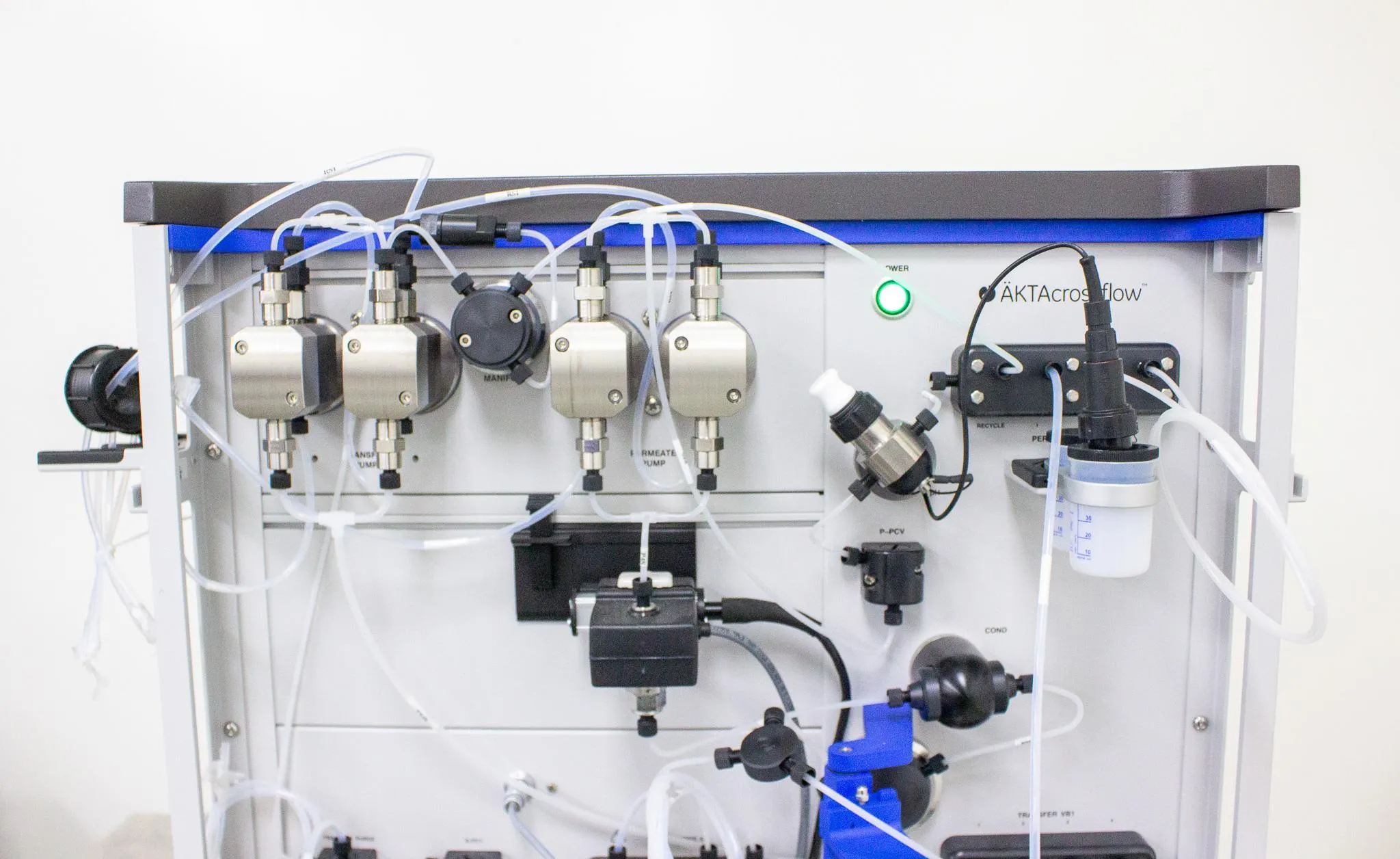

GE AKTAcrossflow Tangential Flow Filtration System 18118000. Preowned instrument from a working environment. Unit has no known issues. We don't have the software to fully test the AKTAcrossflow instrument. Unit is in overall excellent cosmetic condition. System will need to be validated/calibrated to ensure accurate results. 30-day warranty included with purchase. See photos for details. KTAcrossflow is a fully automated tangential flow filtration system for process development and is suitable for filter screening and process optimization at small-scale as well as small-scale processing. Broad range of applications that cover ultrafiltration and microfiltration. Flexible operation of either hollow fiber filter cartridges or cross flow cassettes. Thorough and efficient process development with full TMP and flux scouting. Single, familiar UNICORN interface for both chromatography and tangential flow filtration. Minimum working volume of 25 mL ensures operation of filters between 40 cm and 150 cm. Suitable for small-scale processing where limited material is available. UNICORN control software has the benefits of one common control platform and user interface for all scales of operation in filtration and chromatography. The scouting feature gives automatic support to process development and optimization. Method wizards and pre-programmed methods provide a high degree of efficiency development work. UNICORN is suitable for use in a regulated environment in a manner complying with FDA 21 CFR Part 11. The system can be used with flat sheet cassettes and hollow fibers. A wide range of cross flow devices include MidGeehollow fiber cross flow cartridges and Kvick Startflat sheet cassettes. The cassettes are available in 40 cm2 and 150 cm2 for ultrafiltration as well as diafiltration process development and require small working volume. The AKTACrossflow comes complete with UV, pH and conductivity detectors as well as air, pressure and temperature sensors. The valves and the fittings are specially developed for hygienic, leak-free operation. Electrically actuated diaphragm valves diminish hold up volumes and prevent dead volumes. Specifications: Main Voltage: 100 to 240 V~ 10%, 5060Hz (Auto range) Weight: 70 kg Recirculation Volume Min.:25 ml (with 1.7 mm i.d. tubing kit) Width: 620 mm Application: Well-suited for process development, filter screening, and process optimization at small scale. Compliance: The product fulfills valid directives and standards when used within the conditions specified in the user manual. The product must also be used in the same state as it was delivered from GE Healthcare and connected only to other CE labeled GE Healthcare modules or other products as recommended. For regulatory details please see declaration of conformity. Flow Cell Path Length: 2 mm Connections: UNF 5/16 Wavelength [Zn Lamp]:214 nm Hold-Up Volume Recirculation Line:< 20 ml (with 1.7 mm i.d. tubing kit, empty reservoir) Length: 400 mm Operating Pressure Max.:2 bar (75.4 psi) Material Compliance: USP Class V Height: 650 mm Protection Class: IP 20 Complete Packsize: 1 Piece pH Range: 2–12 Mixing Principle: Magnetic stirrer

Key Features- Fully automated tangential flow filtration system

- Suitable for process development, filter screening, and process optimization at small scale

- Flexible operation of hollow fiber filter cartridges or cross flow cassettes

- Complete with UV, pH, and conductivity detectors as well as air, pressure, and temperature sensors

- Electrically actuated diaphragm valves for hygienic, leak-free operation

- Main Voltage: 100 to 240 V~ 10%, 5060Hz (Auto range)

- Weight: 70 kg

- Recirculation Volume Min.: 25 ml (with 1.7 mm i.d. tubing kit)

- Width: 620 mm

- Application: Well-suited for process development, filter screening, and process optimization at small scale

- Compliance: The product fulfills valid directives and standards when used within the conditions specified in the user manual. The product must also be used in the same state as it was delivered from GE Healthcare and connected only to other CE labeled GE Healthcare modules or other products as recommended. For regulatory details please see declaration of conformity.

- Flow Cell Path Length: 2 mm

- Connections: UNF 5/16

- Wavelength [Zn Lamp]:214 nm

- Hold-Up Volume Recirculation Line:< 20 ml (with 1.7 mm i.d. tubing kit, empty reservoir)

- Length: 400 mm

- Operating Pressure Max.:2 bar (75.4 psi)

- Material Compliance: USP Class V

- Height: 650 mm

- Protection Class: IP 20

- Complete Packsize: 1 Piece

- pH Range: 2–12

- Mixing Principle: Magnetic stirrer

Metric: 70 kg

Imperial: 154.32 lb

Metric: 62.0 cm x 29.0 cm x 65.0 cm

Imperial: 24.41 in x 11.42 in x 25.59 in

842121

Harmonized Code DetailsCentrifuges; filtering or purifying machinery and apparatus, for liquids or gases

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”