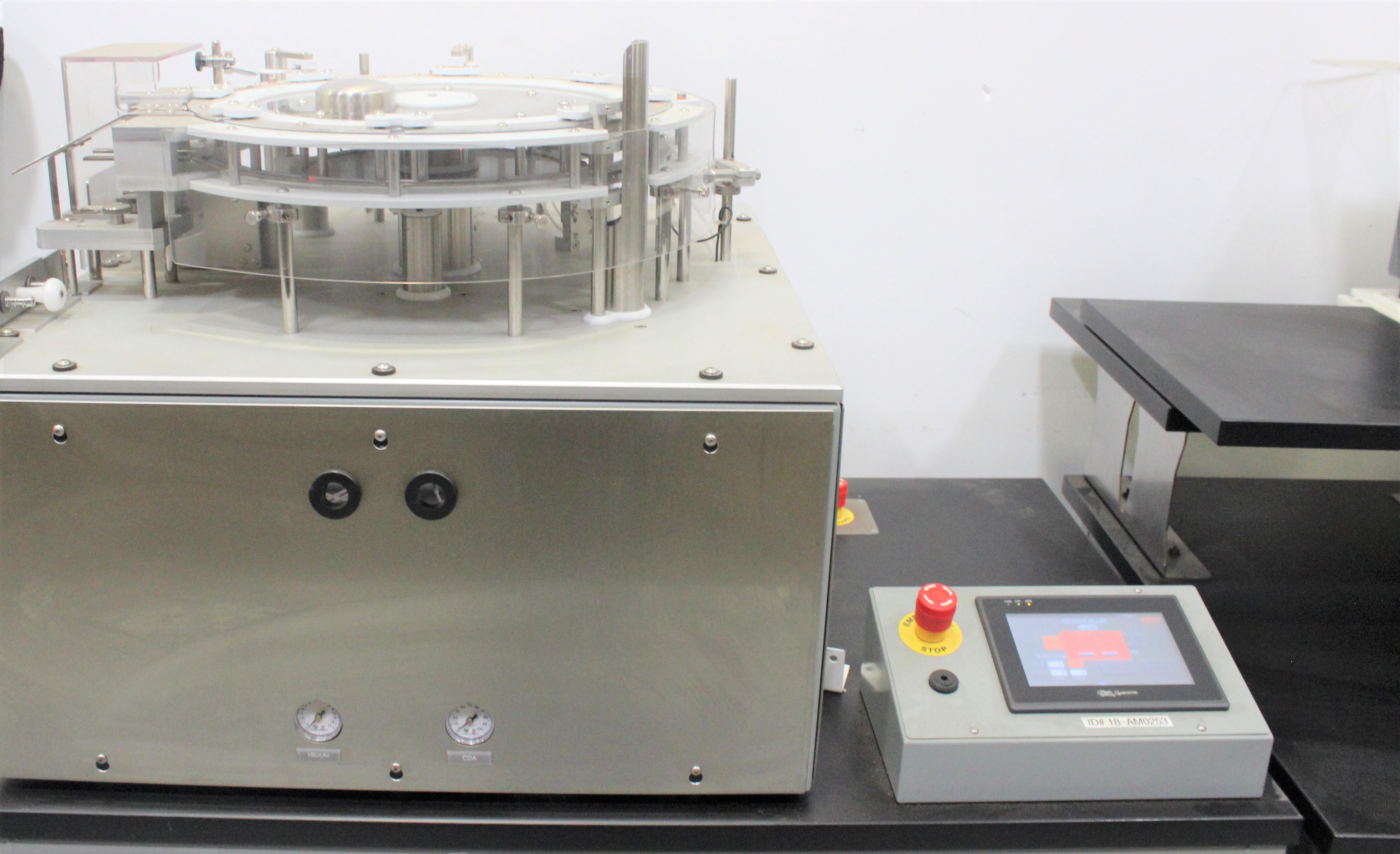

Landry Filling Station Pharmaceutical Automation Vibratory Feeders 2015 Model

Landry Engineering Development LLC

Details

-

CategoryProduction / Manufacturing

-

Dimension40.0in x 166.0in x 80.0in

-

SerialN/A

-

Shipping TypeFreight

-

ManufacturingDoes Not Apply

-

Voltage / Hertz120V/220V / 50Hz/60Hz

Description

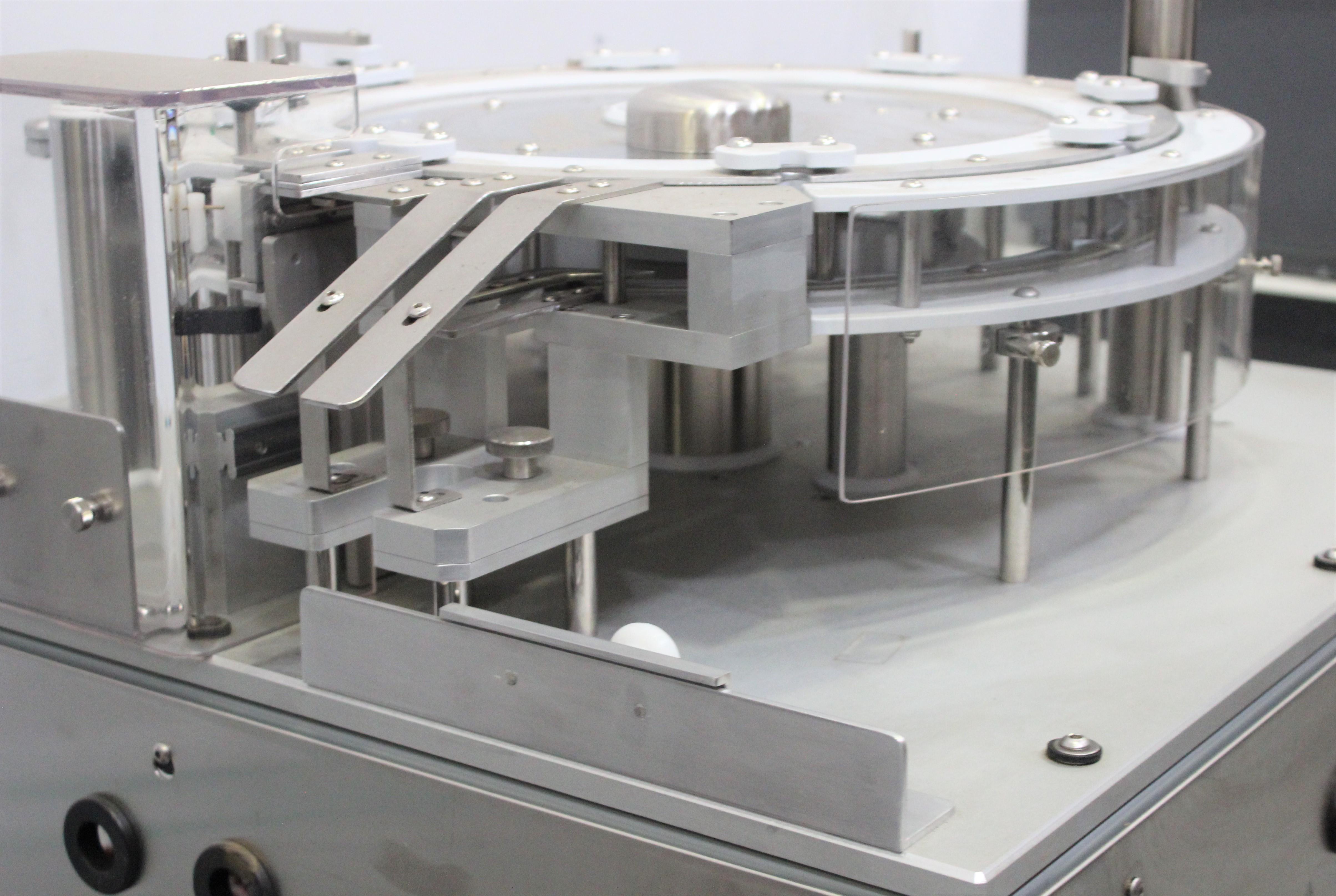

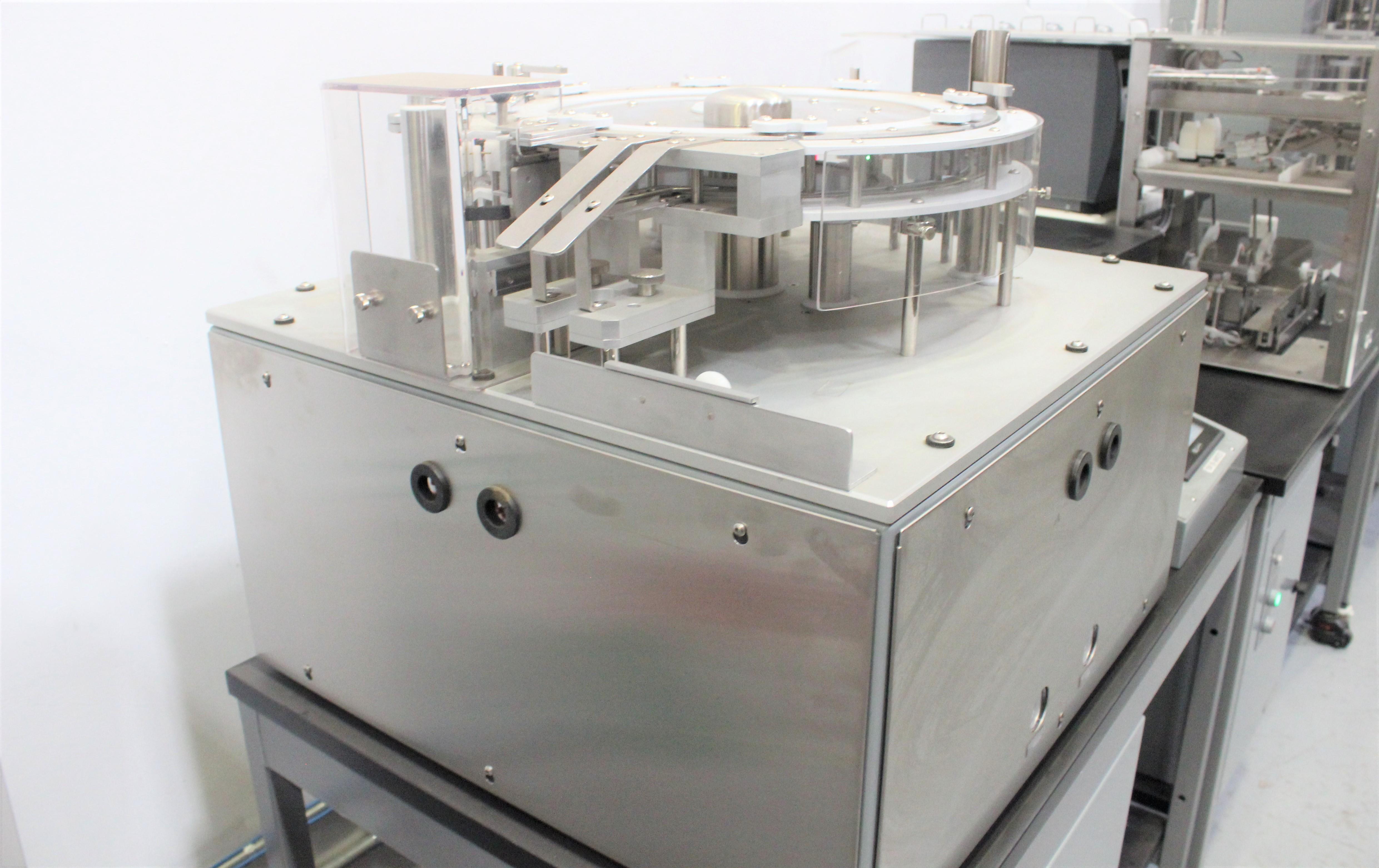

The Landry Engineering Syringe Filling Station, constructed in 2015, features TechnaVibes Vibratory Feeders to automate the process of filling and packaging 3mL syringes. Designed to precision-fill small volumes of Fluorinert, this custom-built unit by Landry Engineering degasses the inert gas, facilitates label printing on envelopes, and utilizes bowl feeders to transport syringes and caps. Although minimally trialed, this system remains efficient, with a central component for label application, and a tall cabinet for chemical degassing. This used unit, despite minor cosmetic wear, operates as intended, supporting full functionality and operation. It provides a robust solution for pharmaceutical filling and packaging applications with prescribed volume filling, capping, verification, rejection, and pouch labeling capabilities.

Key Features

- TechnaVibes Vibratory Feeders for automated cap and syringe delivery

- Central labeling system for efficient packaging

- Tall cabinet for chemical degassing

- Custom-built unit by Landry Engineering

- Operational status with valid function tests

Specifications

- Designed for 3mL syringe filling with Fluorinert

- Includes a degassing system for inert gas handling

- Vibratory feeders for automatic cap and syringe delivery

- Label printing and envelope system for end-to-end packaging

- Operates on 120V/220V, 50Hz/60Hz power configuration

Weight

Imperial: 2400.0 Pounds

Metric: 1088.62 Kilograms

Shipping Dimensions

Imperial: 48.0 lb x 199.2 lb x 96.0 lb

Metric: 121.92 cm x 505.97 cm x 243.84 cm

Harmonized Code

842230

Harmonized Code Details

842230 - Machinery for filling, closing, sealing, or labeling bottles, cans, bags or other containers; included in this category due to its function in automating the filling and packaging process for pharmaceutical syringes.

Comments 0

There are currently no public comments.