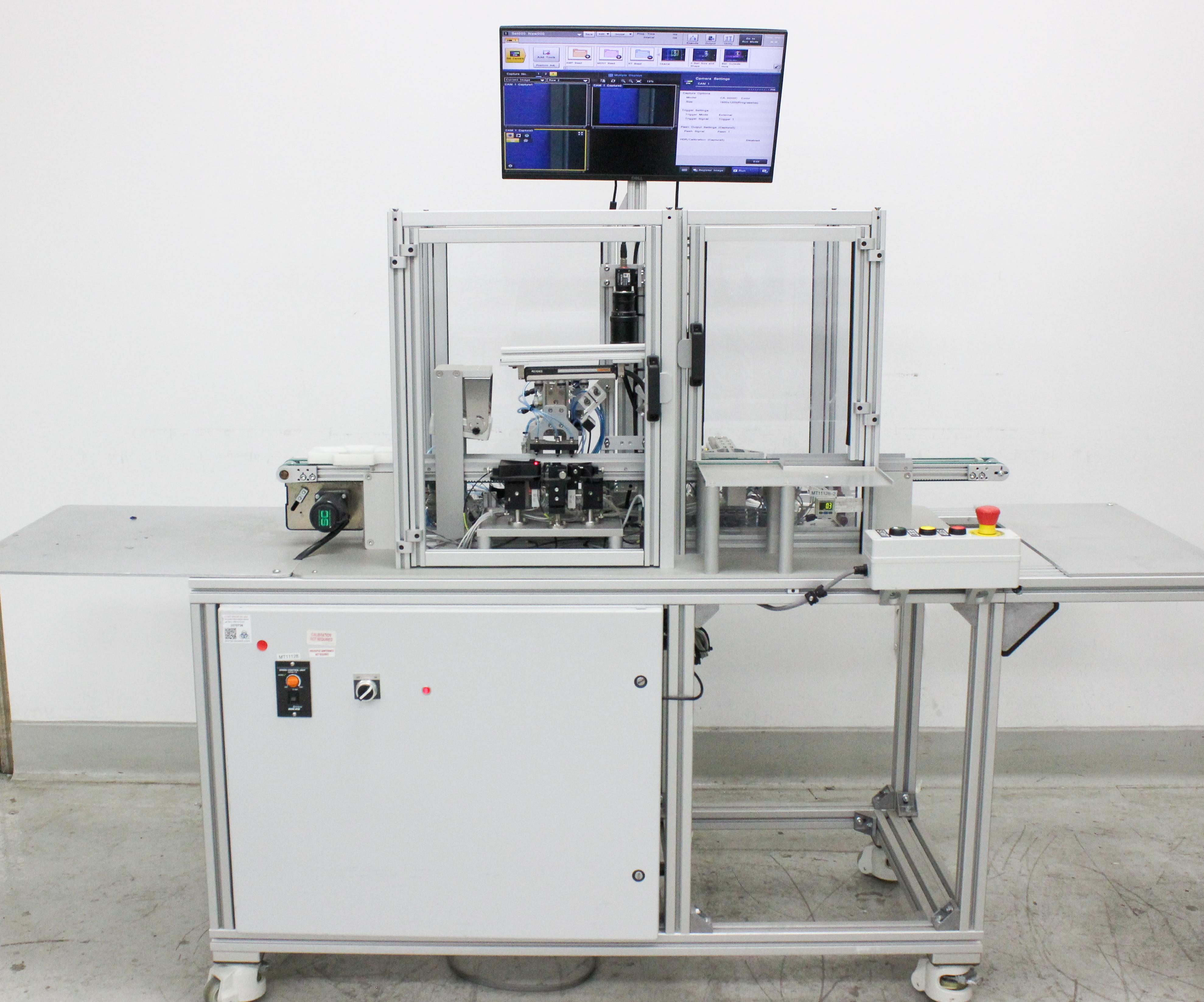

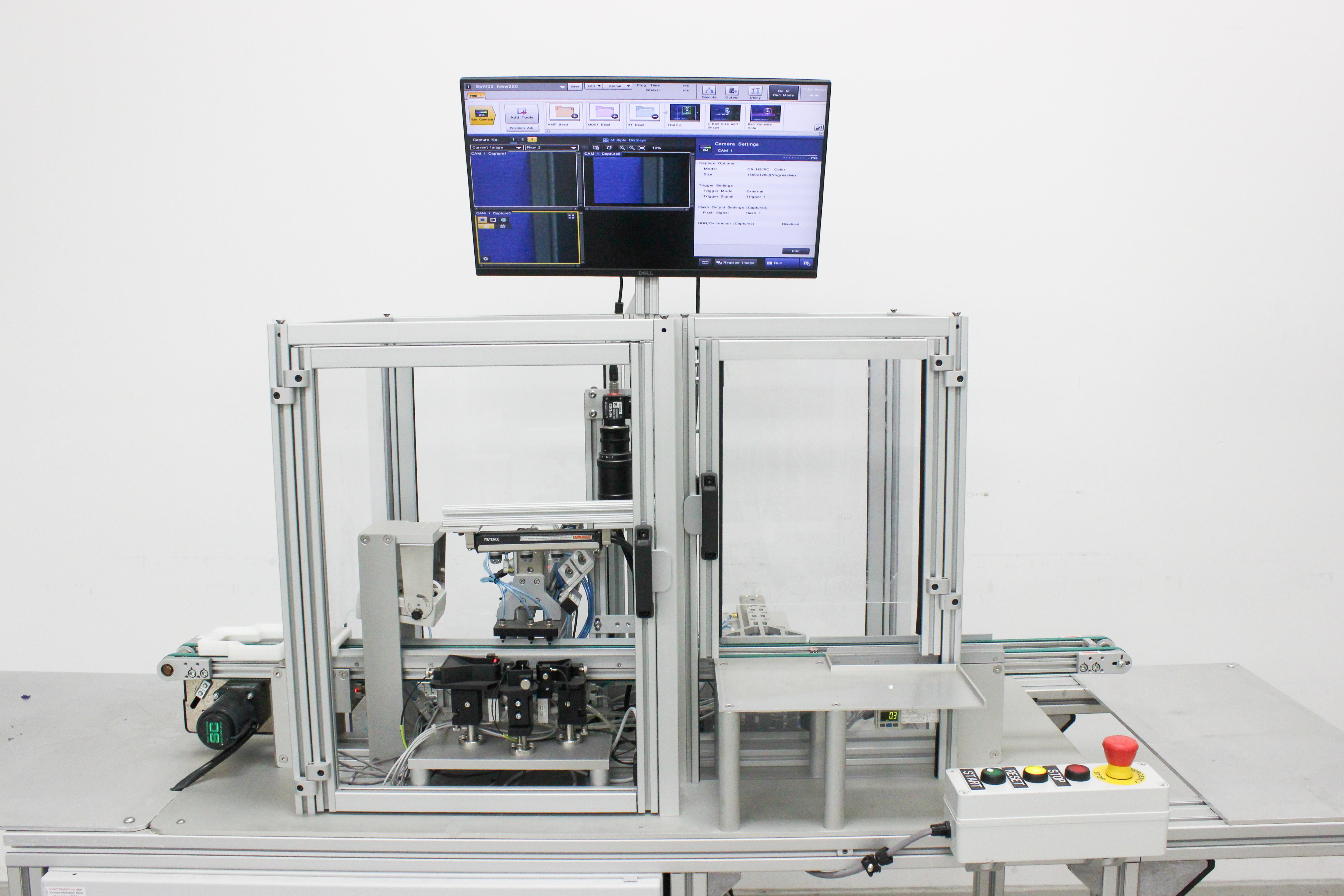

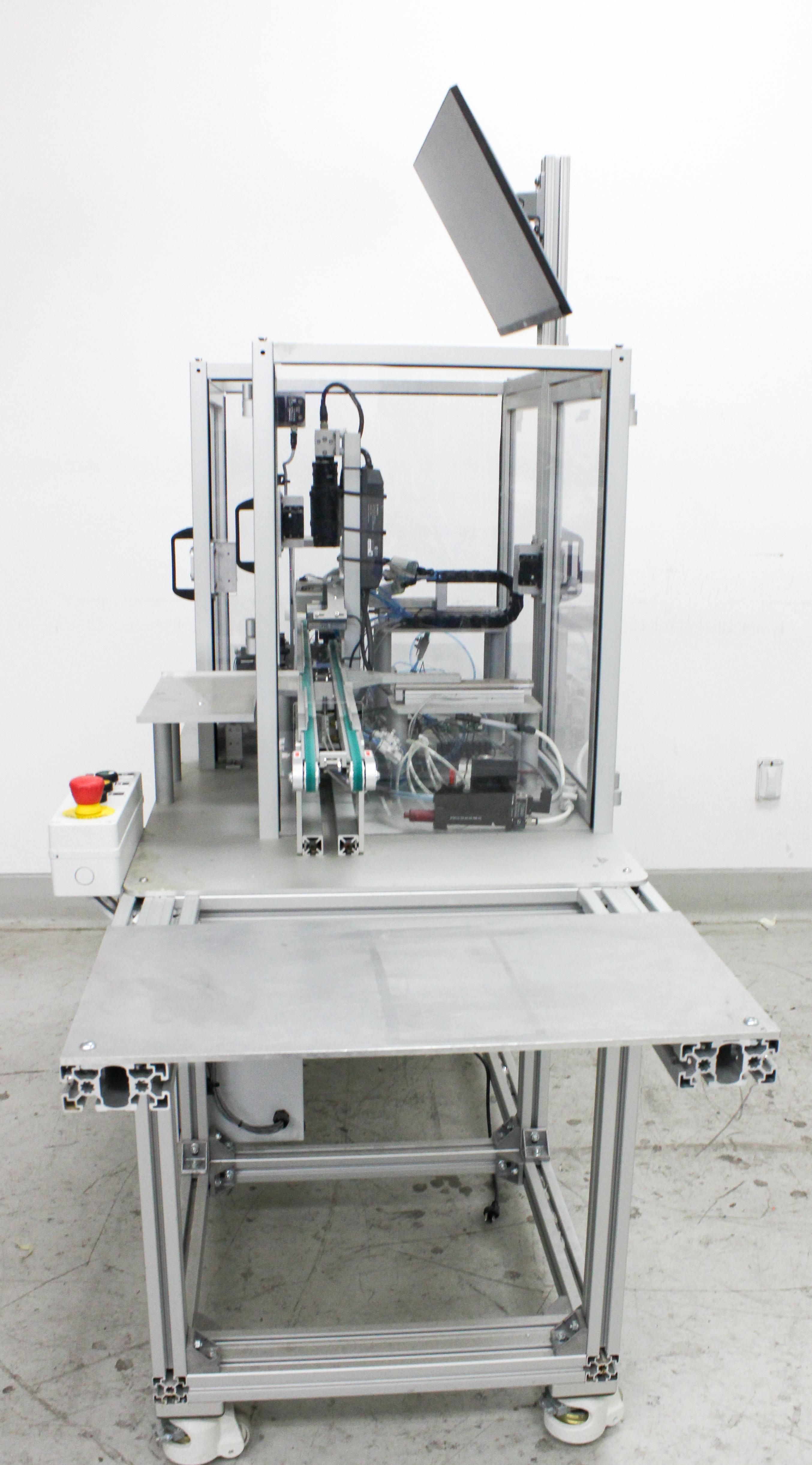

Ridgeline Keyence 236-001 Pick and Place Machine Custom Vision 2020

Ridgeline Engineering/Keyence

Details

-

CategoryProduction / Manufacturing

-

Dimension27.0in x 89.0in x 57.0in

-

Serial23603-02

-

Shipping TypeFreight

-

Manufacturing2020-12-01

-

Voltage / Hertz120V / 60Hz US

Description

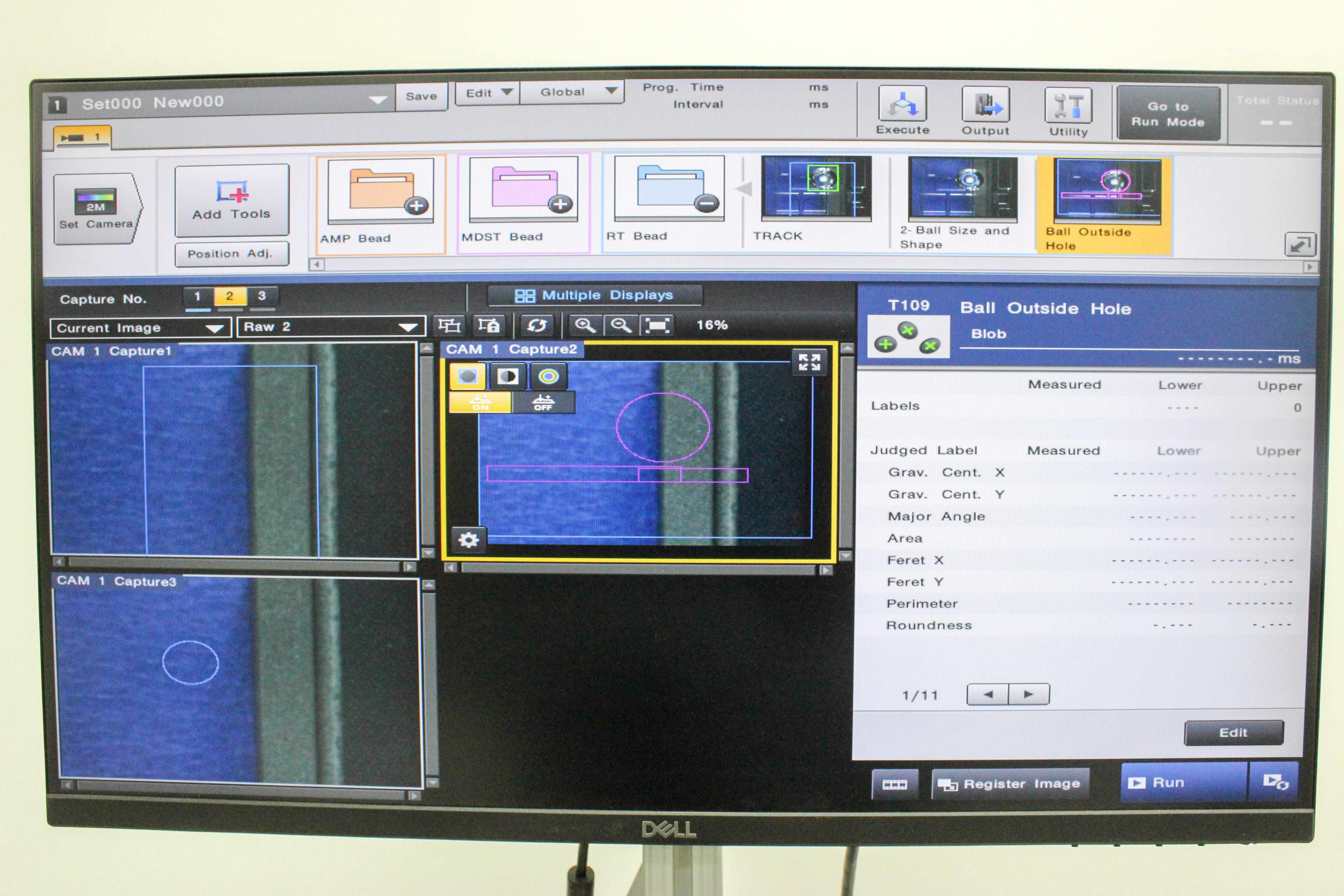

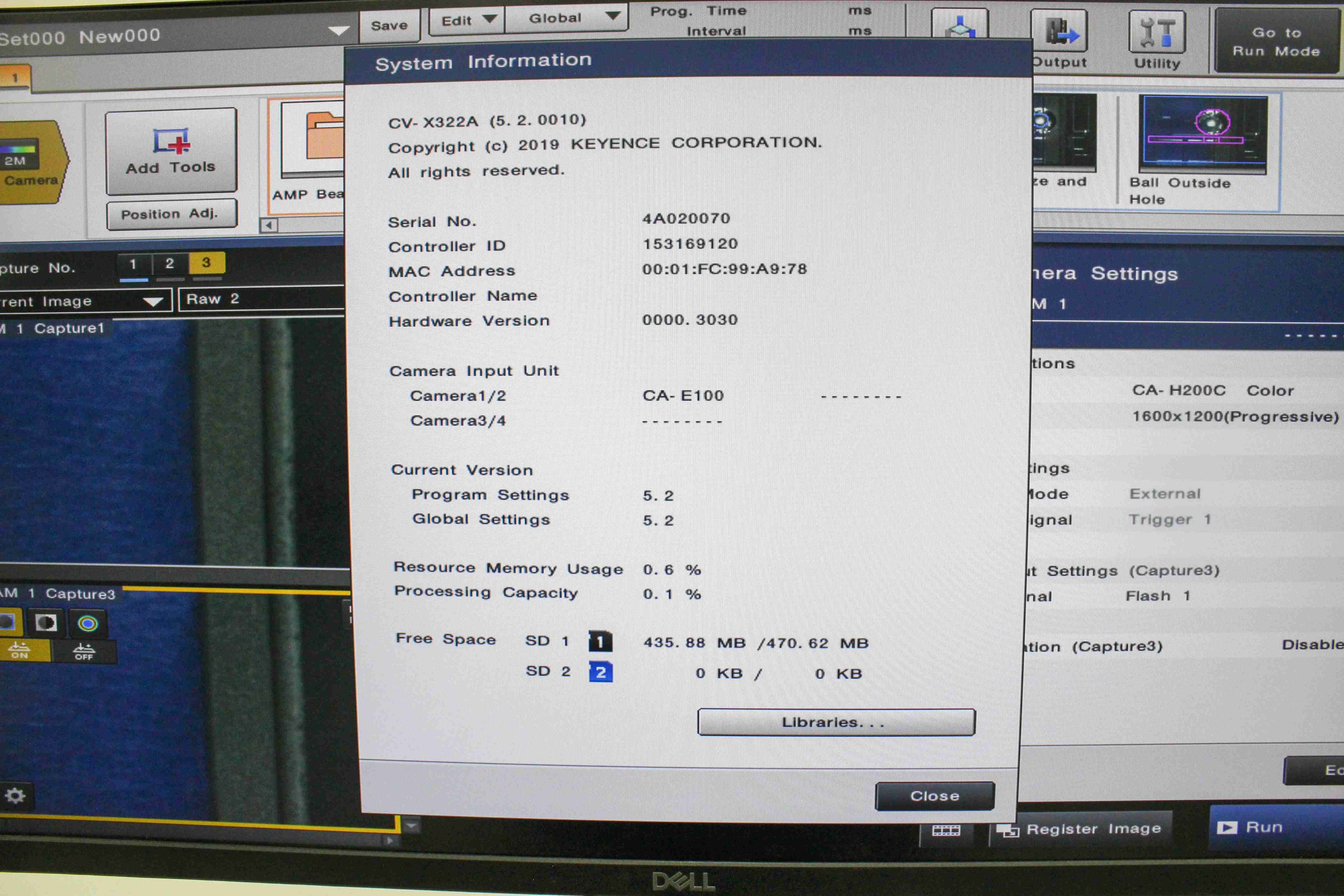

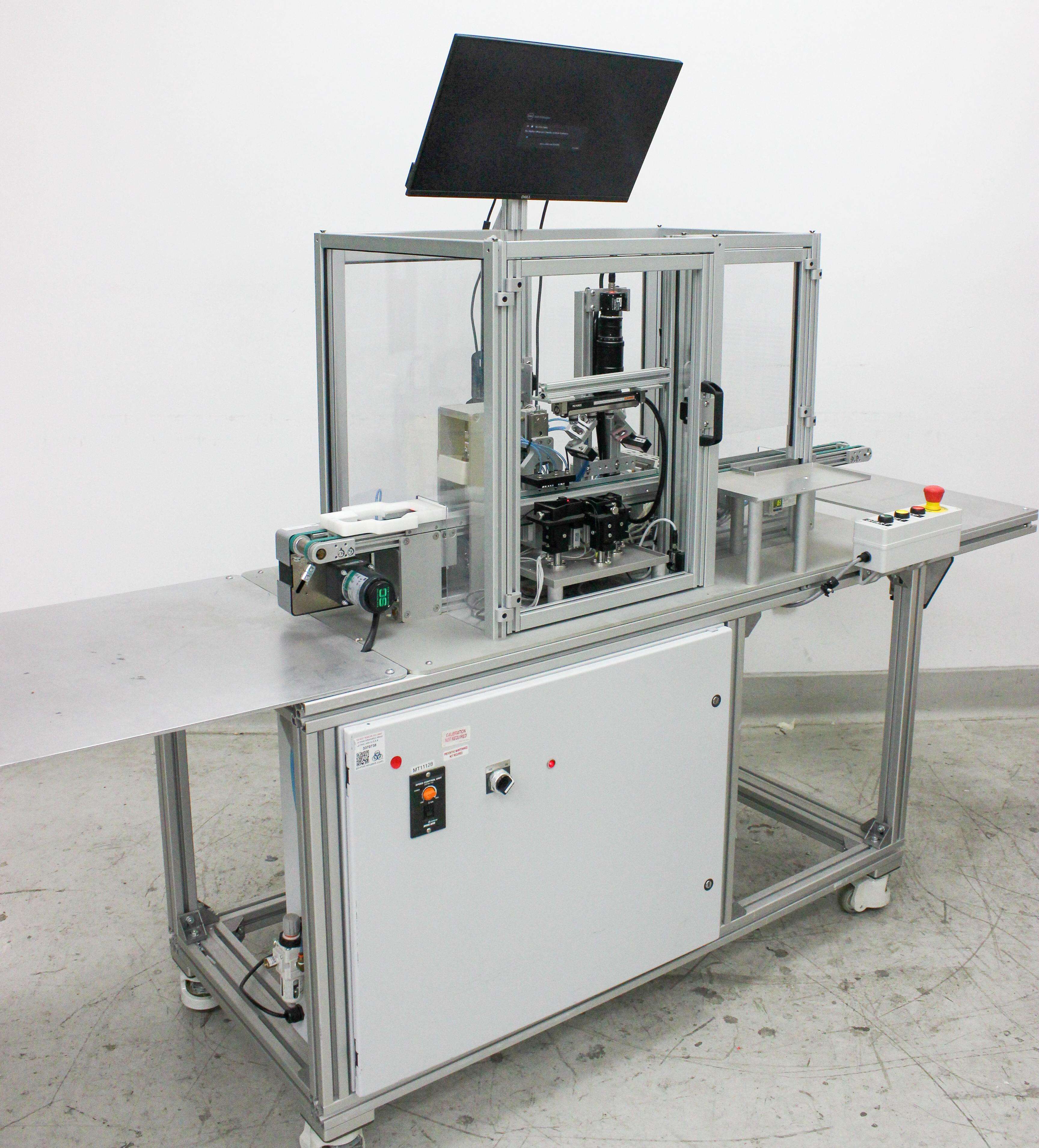

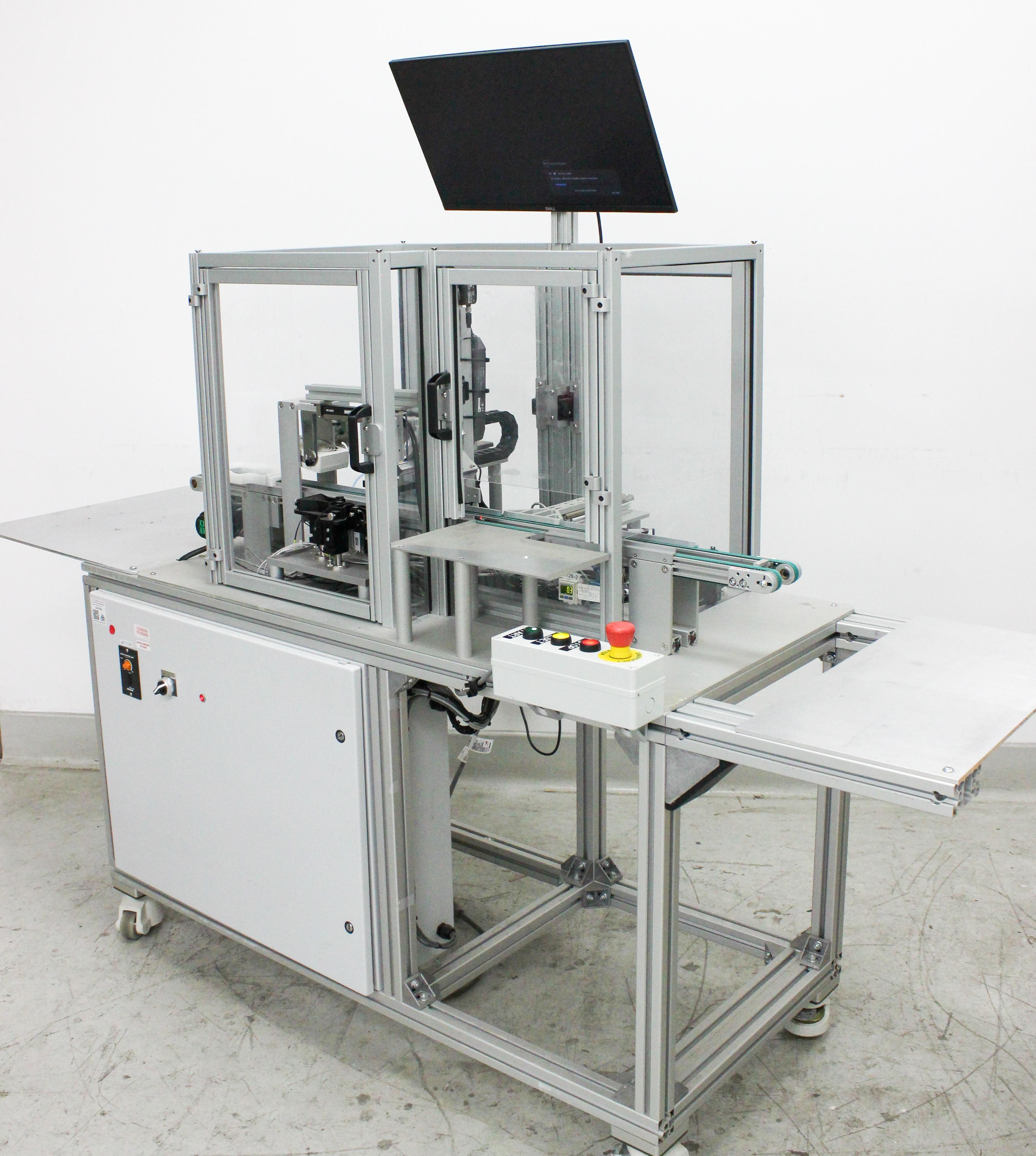

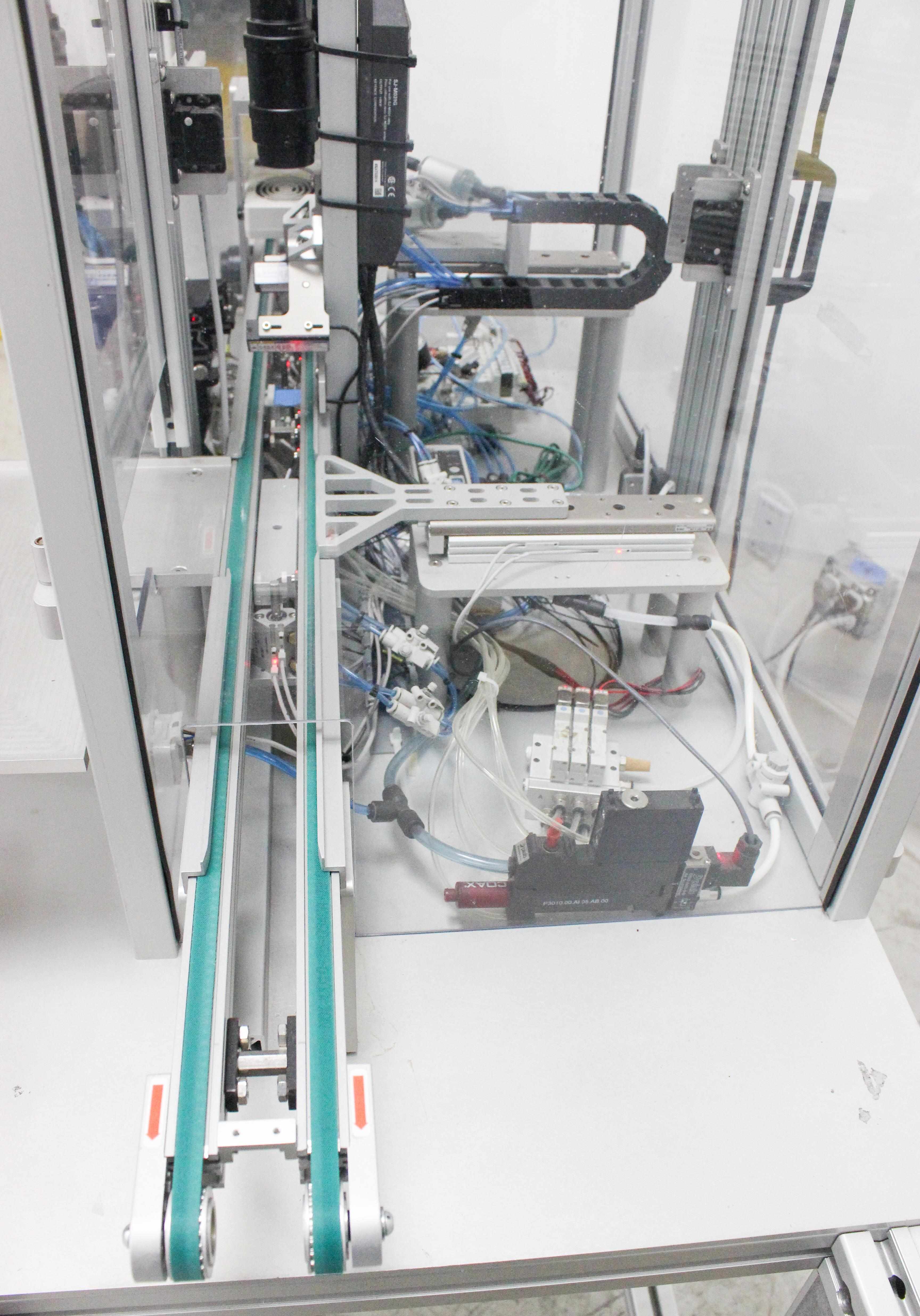

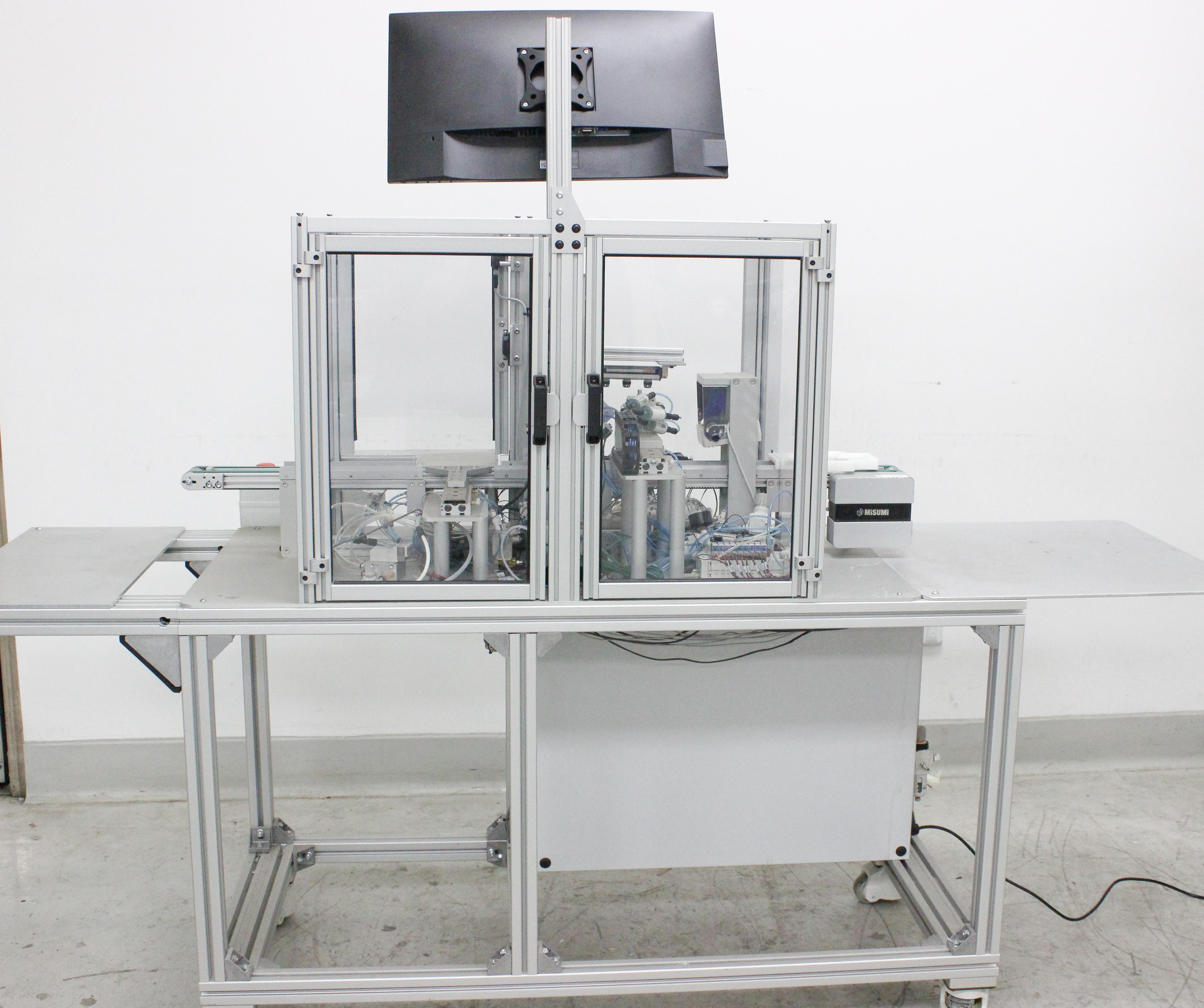

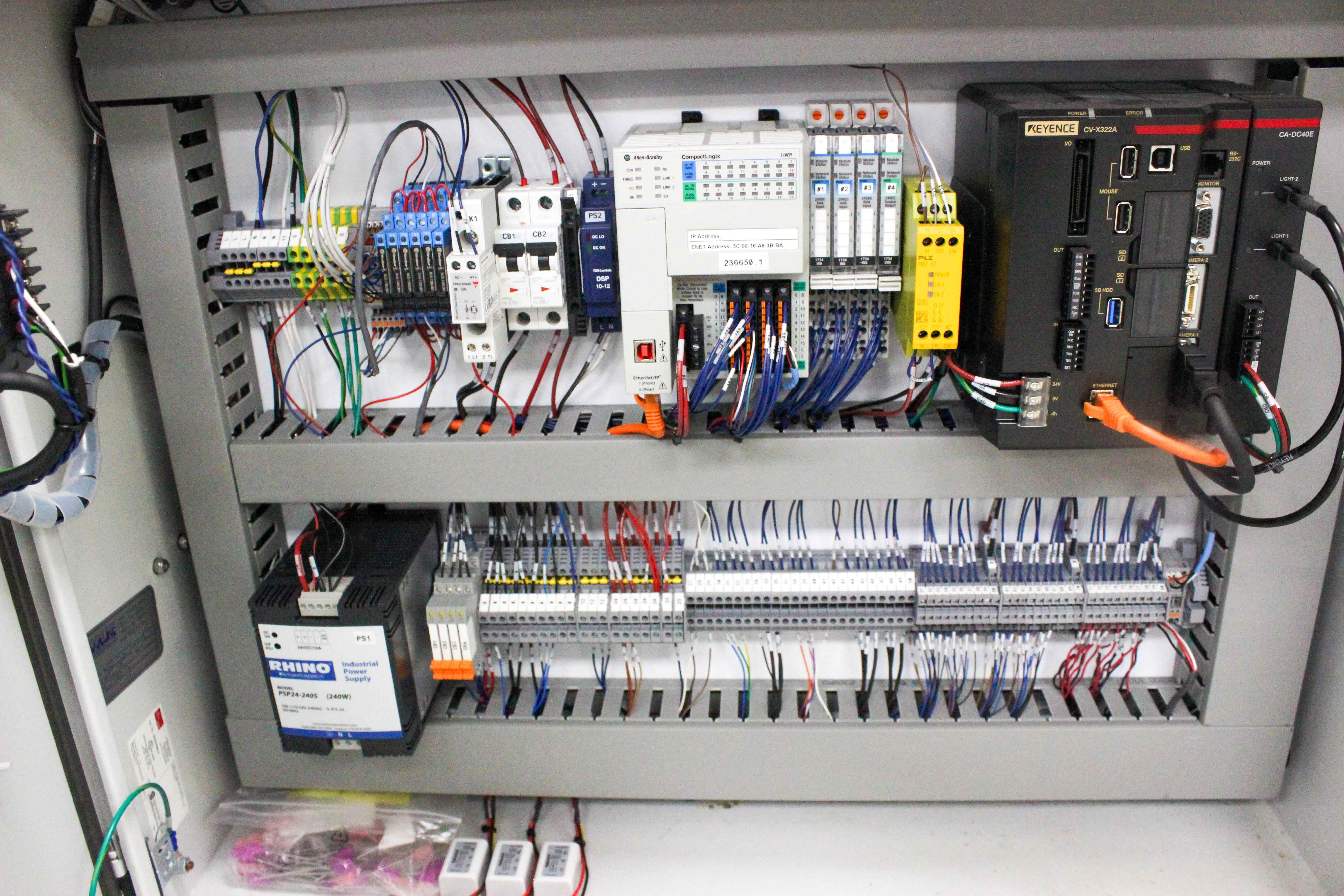

This Ridgeline Engineering/Keyence 236-001 Three Bead Pick and Place Machine, manufactured in 2020, is an advanced robotic system used for efficient and precise assembly tasks. Specially designed for handling bead-like components, it can simultaneously manage three units for improved productivity and accuracy in manufacturing processes. Equipped with a Keyence CV-X322A vision system, this machine supports high-definition image processing, enabling precise inspection and detection of minute defects. The system features integrated LED lighting controls and allows for seamless data integration with other factory automation equipment. While the machine powers on and appears functional, it shows typical signs of wear and the enclosure's front glass window is missing.

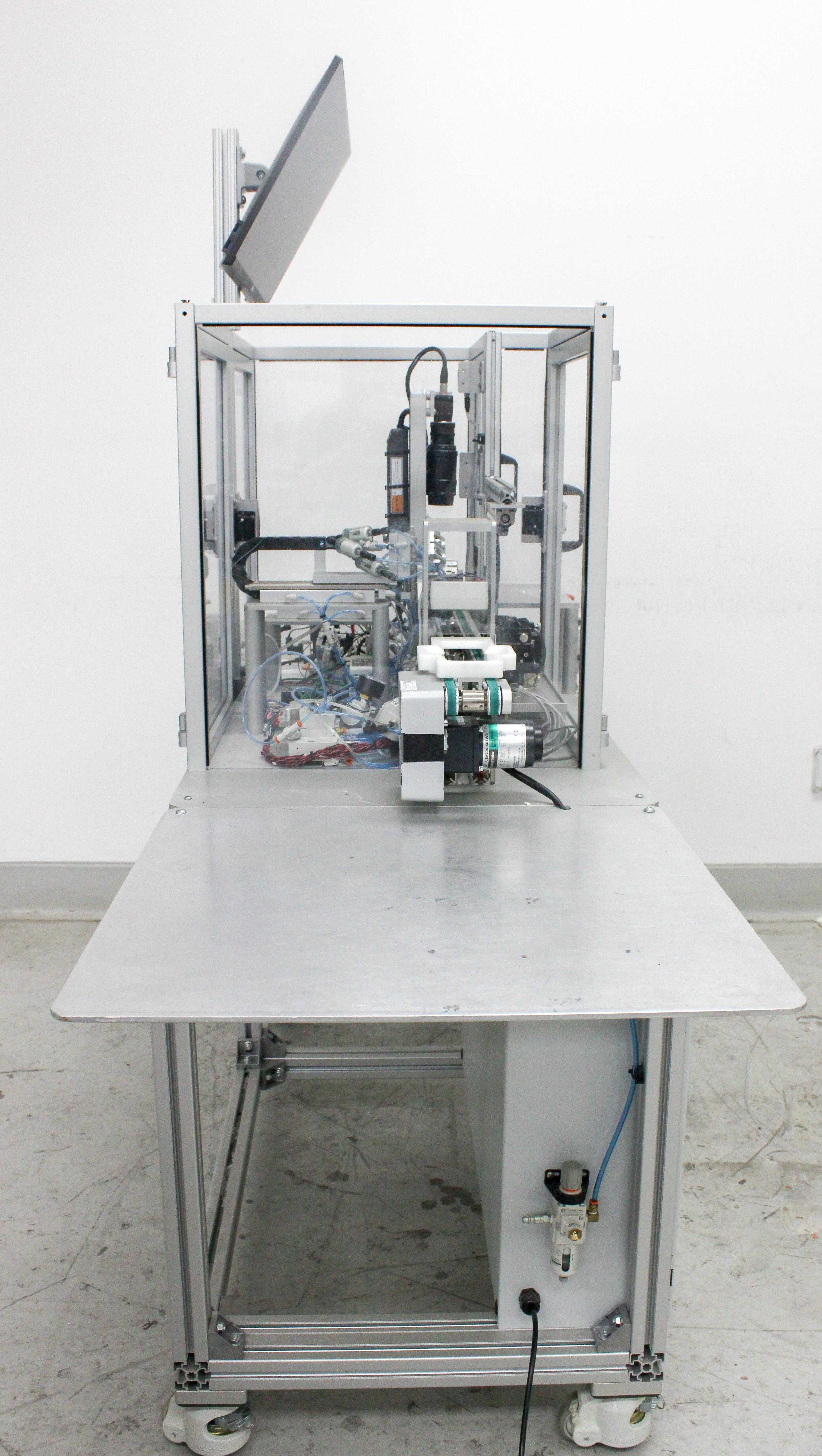

Technician comment

Custom-built pick and place machine designed for the production of Accula test cartridges. It features an integrated vision inspection system, a conveyor, and a control panel housed within an enclosure, all mounted on a mobile workstation. The system powers on, and the camera is operational. The unit shows typical signs of wear from regular use, and notably, the front glass window of the enclosure is missing. Please see the attached photos for additional details.

Key Features

- Integrated Keyence CV-X322A vision system

- Simultaneous handling of three bead components

- High-definition image processing

- LED lighting control for optimized inspections

- Data integration capability with factory systems

- Custom-built for Accula test cartridges

Specifications

- Power: 120V, 60Hz

- Integrated Vision System: Keyence CV-X322A, 2-megapixel camera

- Manufacture Date: December 1, 2020

- Condition: Used, functional with minor wear

- Includes: Power cord and data cables

- Missing: Front glass window of enclosure

- Control: Mounted on a mobile workstation with control panel

- Application: Suitable for bead component assembly and inspection

Weight

Imperial: 360.0 Pounds

Metric: 163.29 Kilograms

Shipping Dimensions

Imperial: 32.4 lb x 106.8 lb x 68.4 lb

Metric: 82.3 cm x 271.27 cm x 173.74 cm

Harmonized Code

847989

Harmonized Code Details

847989 - Machines and mechanical appliances having individual functions, not specified or included elsewhere; parts thereof: Other. This code is applicable due to the specific custom build and function of the pick and place system.

Comments 0

There are currently no public comments.