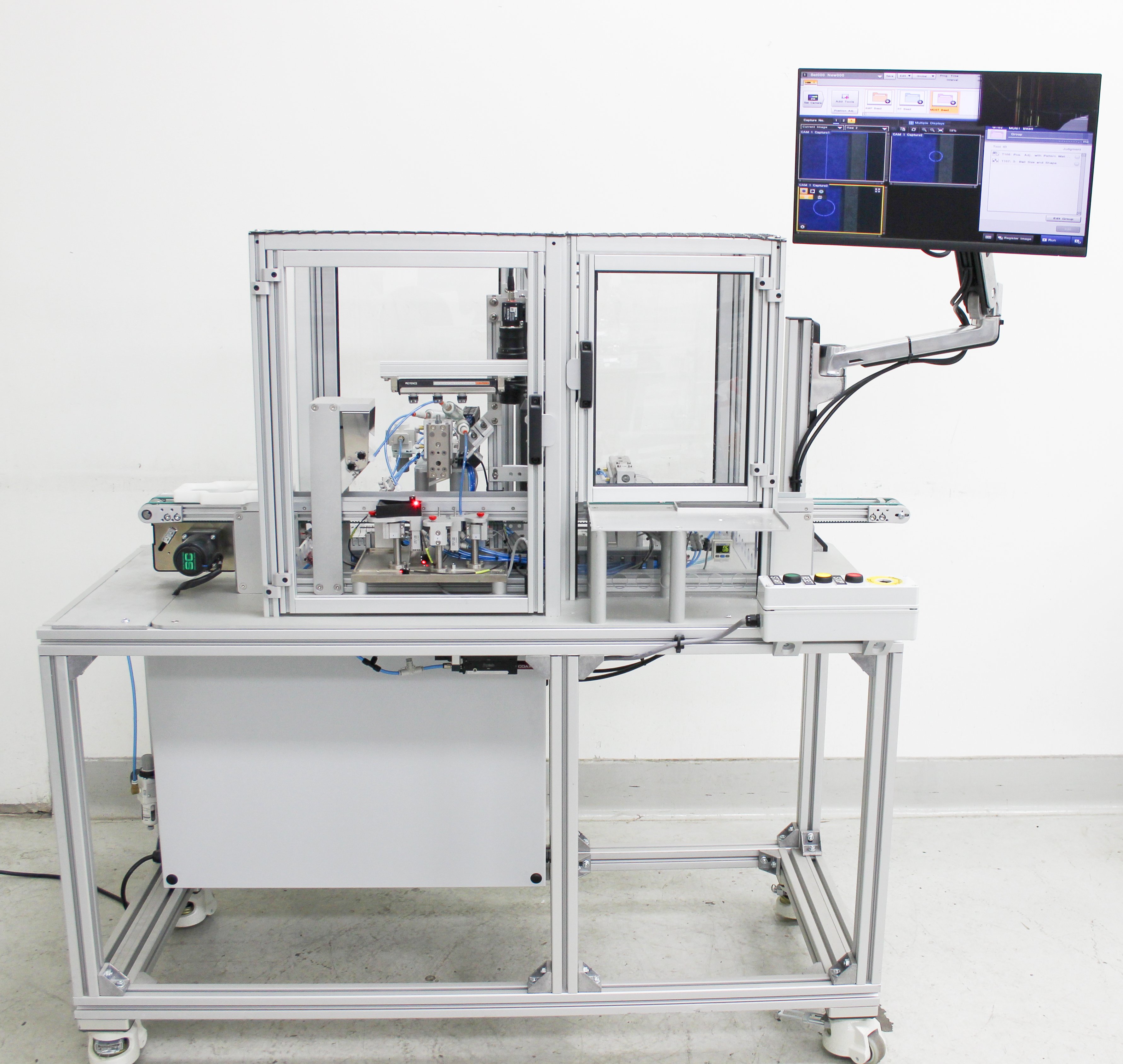

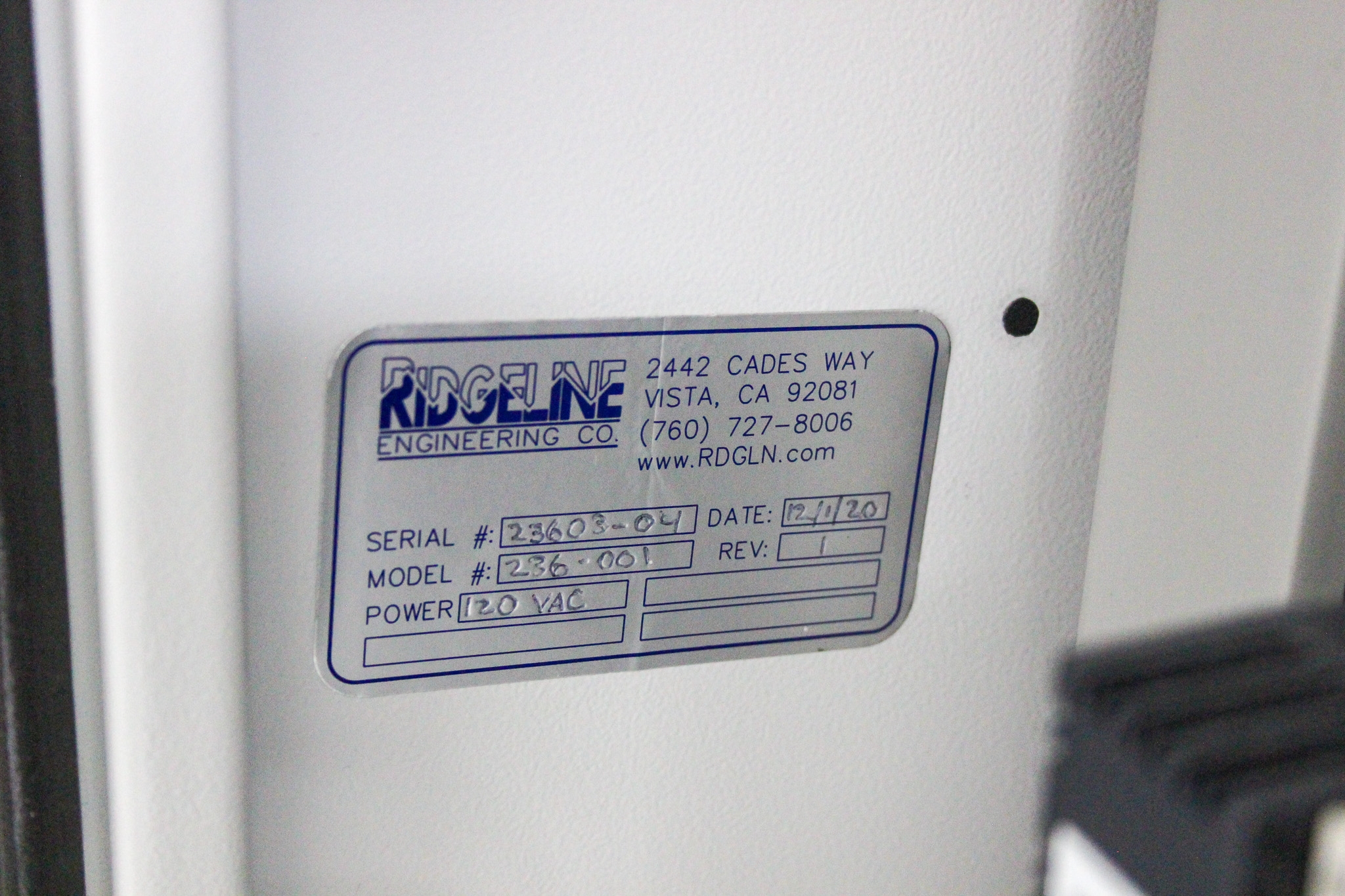

Ridgeline 236-001 Pick and Place Vision Machine Conveyor 120V Fair Condition

Ridgeline Engineering

Details

-

CategoryProduction / Manufacturing

-

Dimension27.0in x 60.0in x 73.0in

-

Serial2360304

-

Shipping TypeFreight

-

ManufacturingDoes Not Apply

-

Voltage / Hertz120V / 50Hz/60Hz

Description

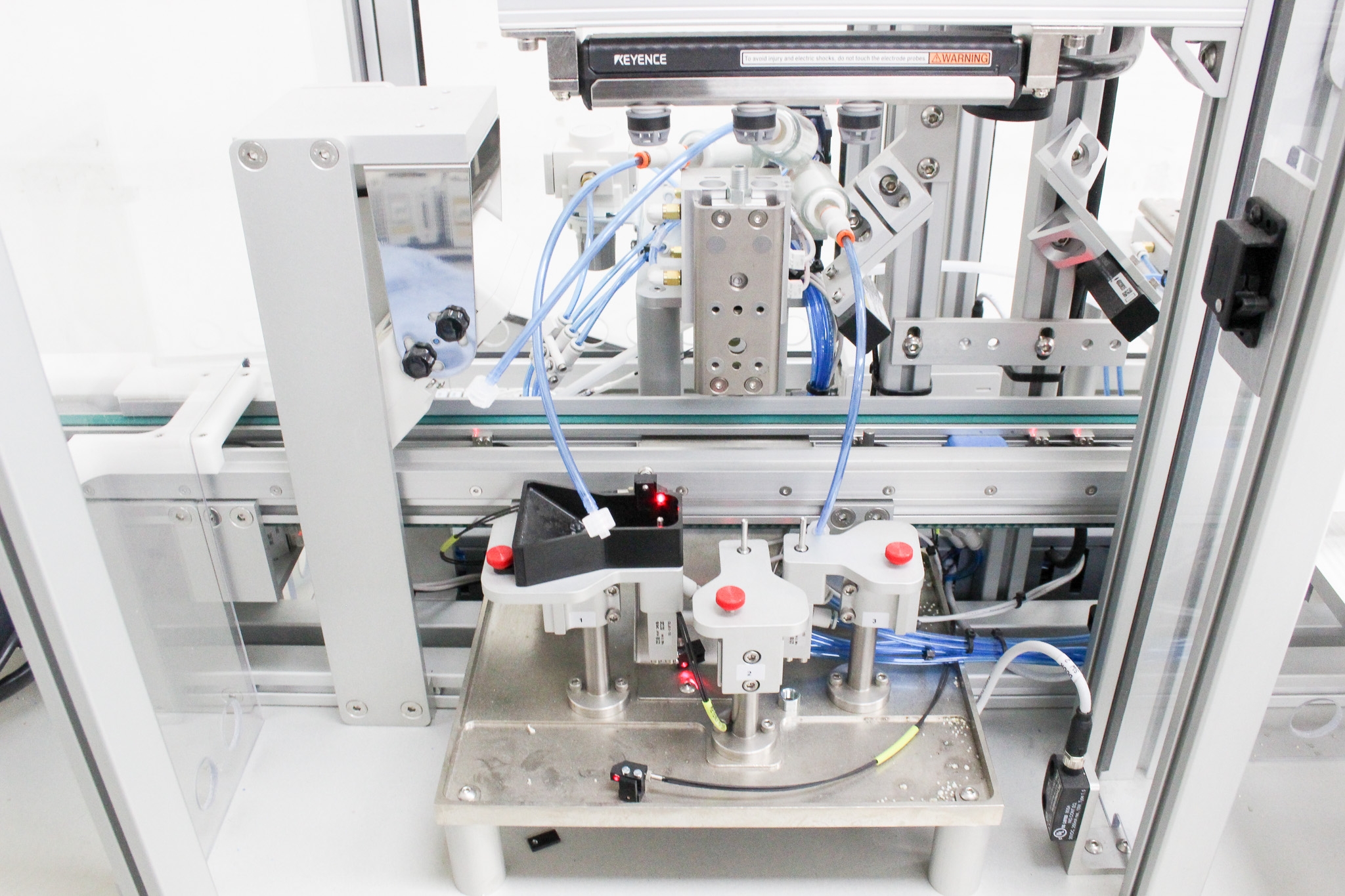

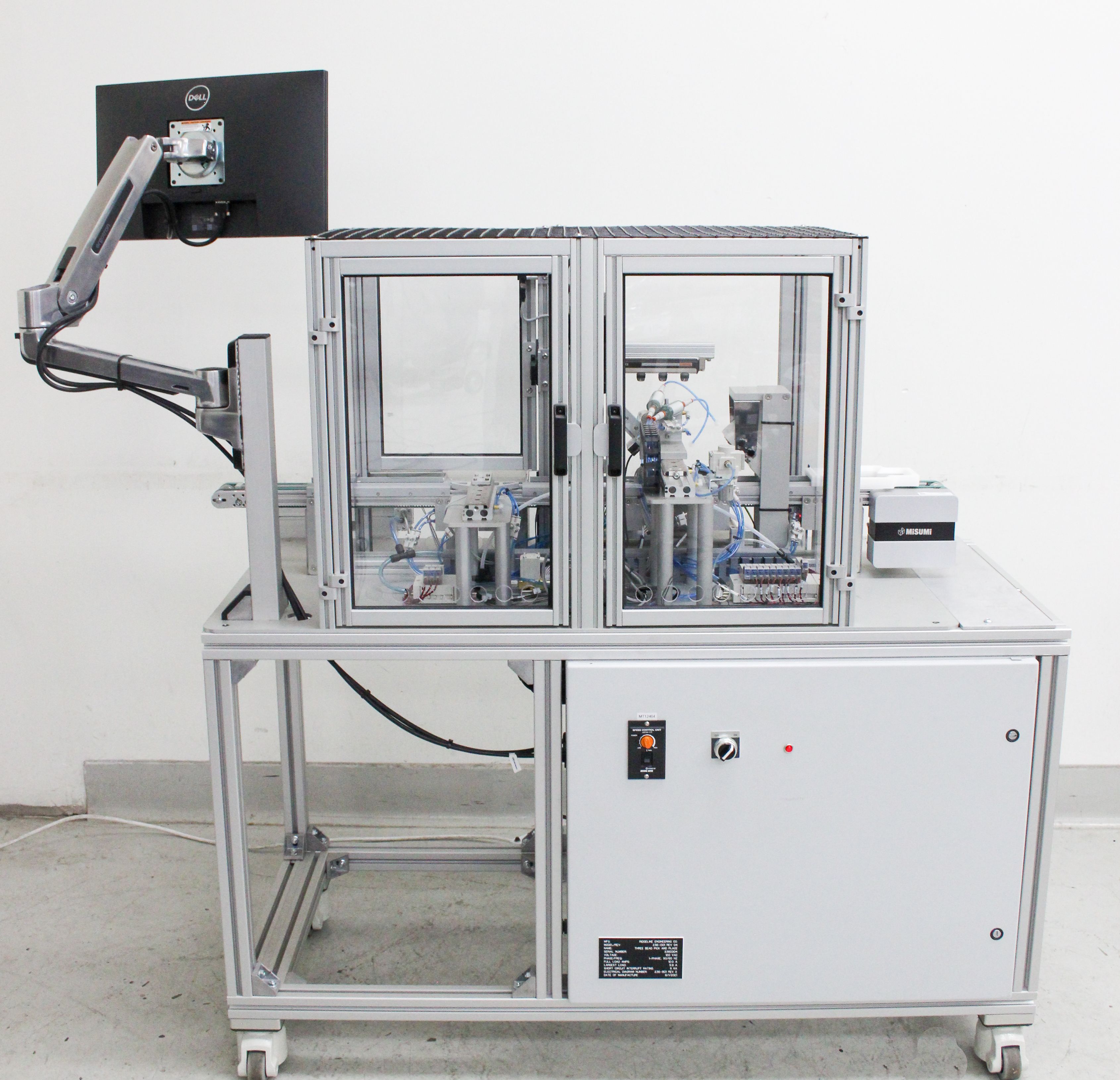

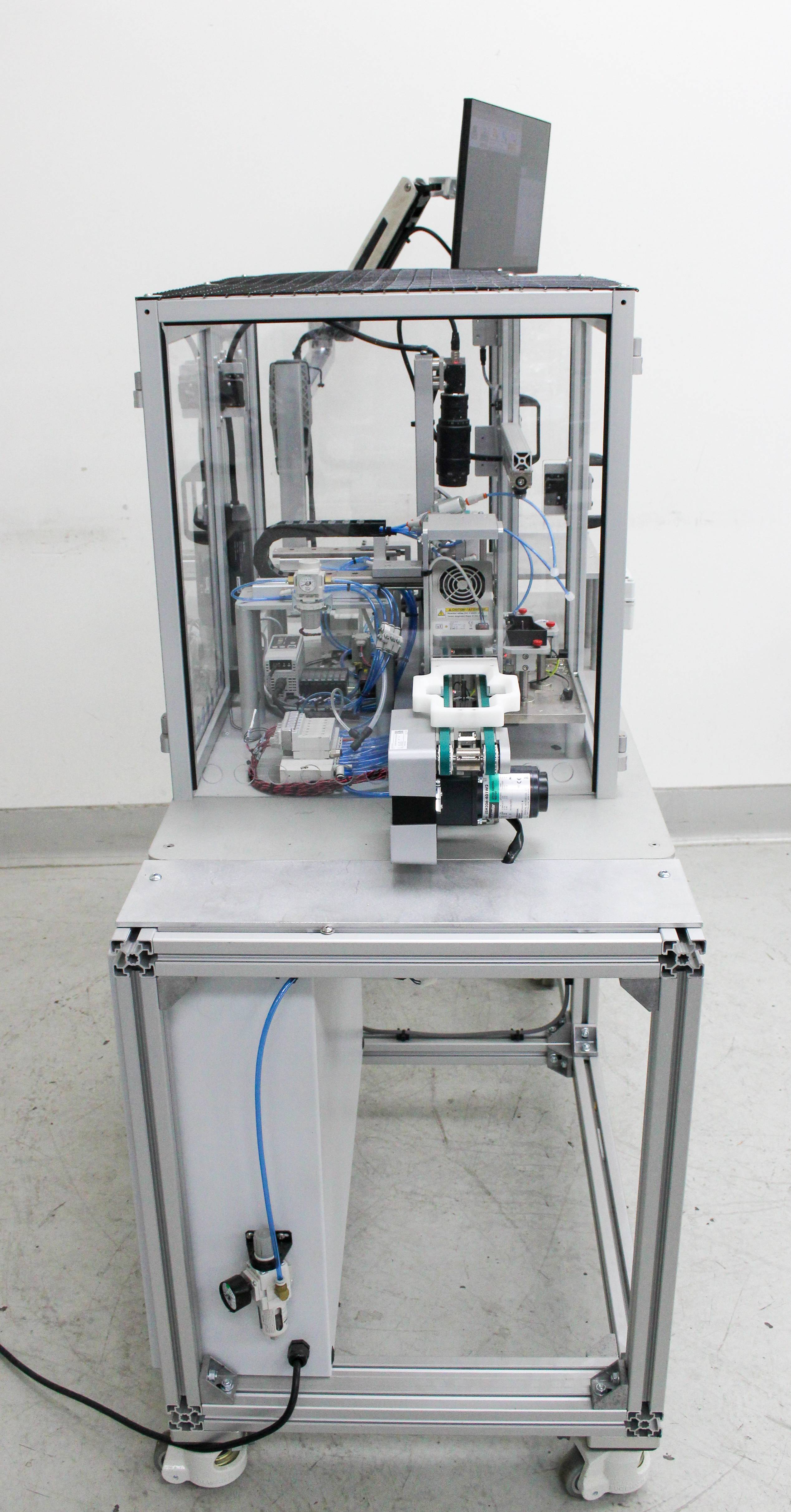

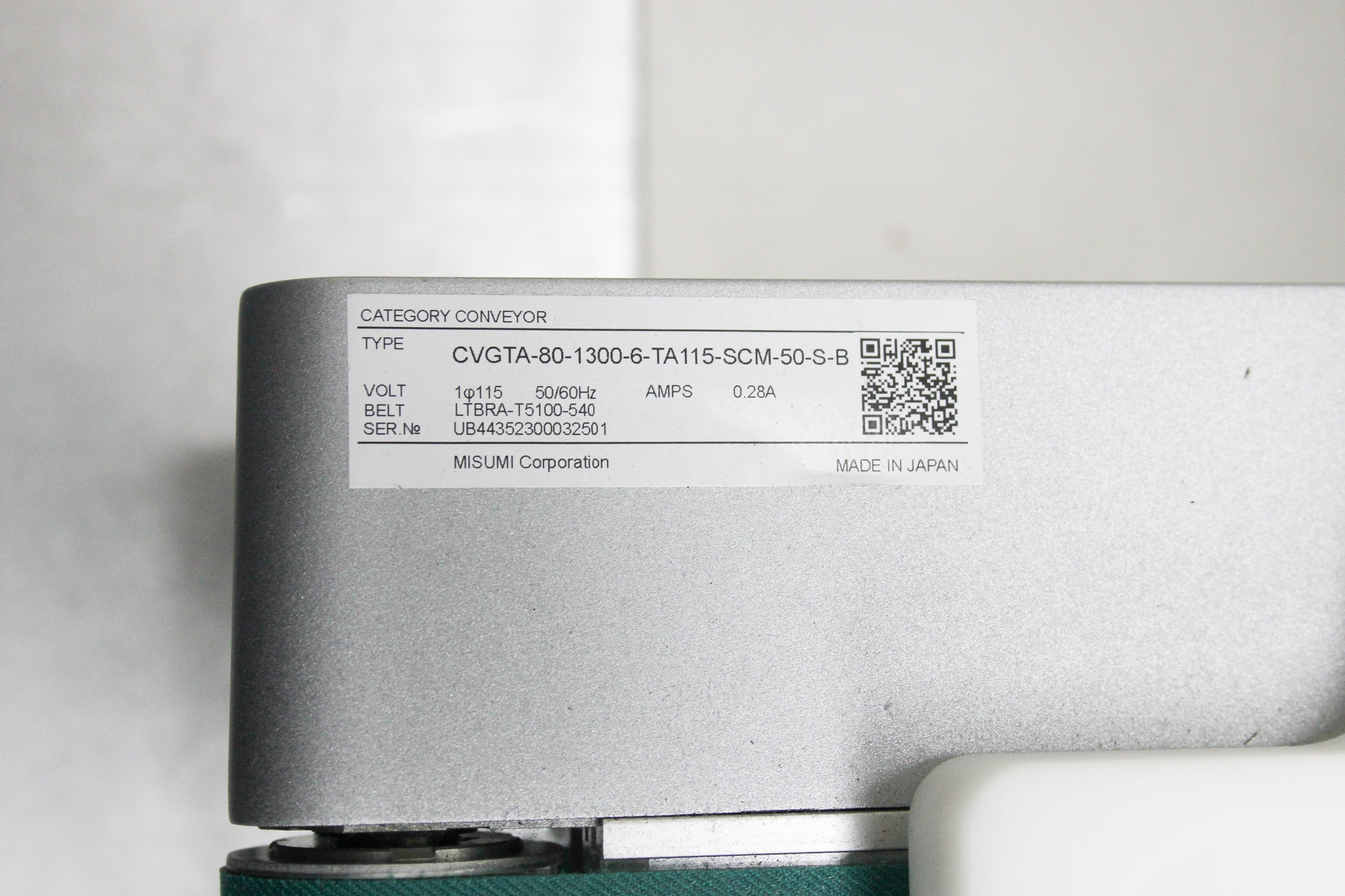

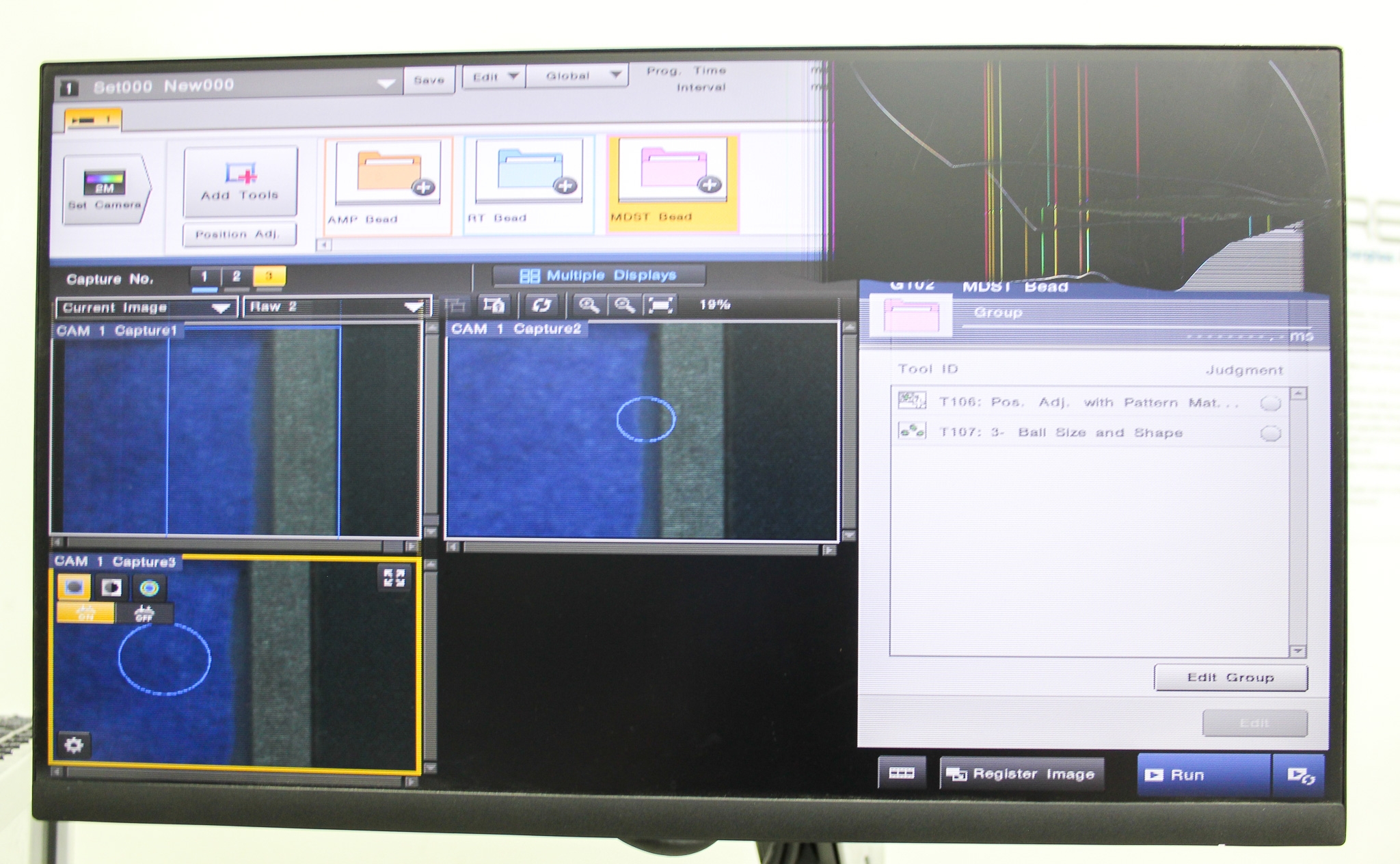

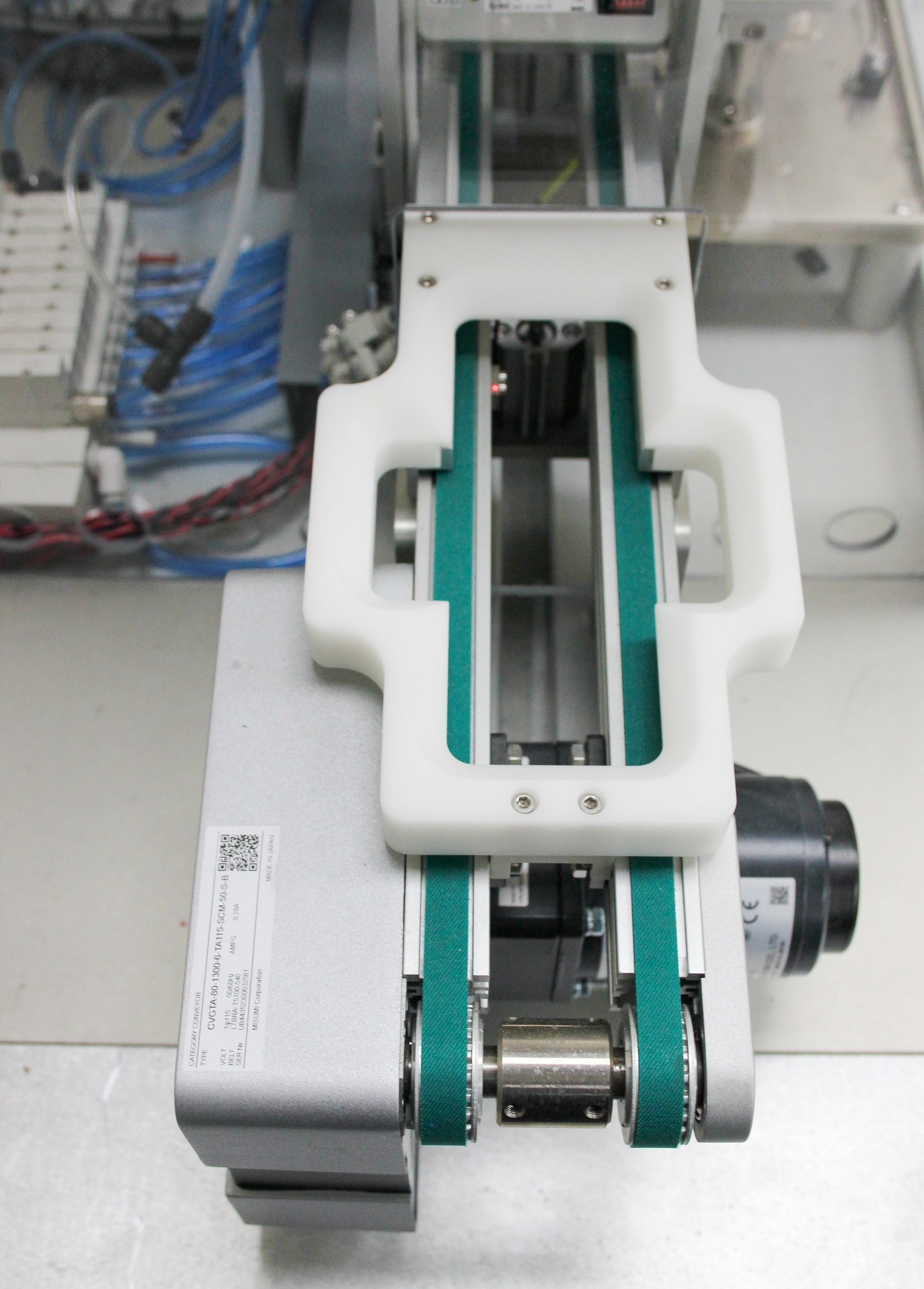

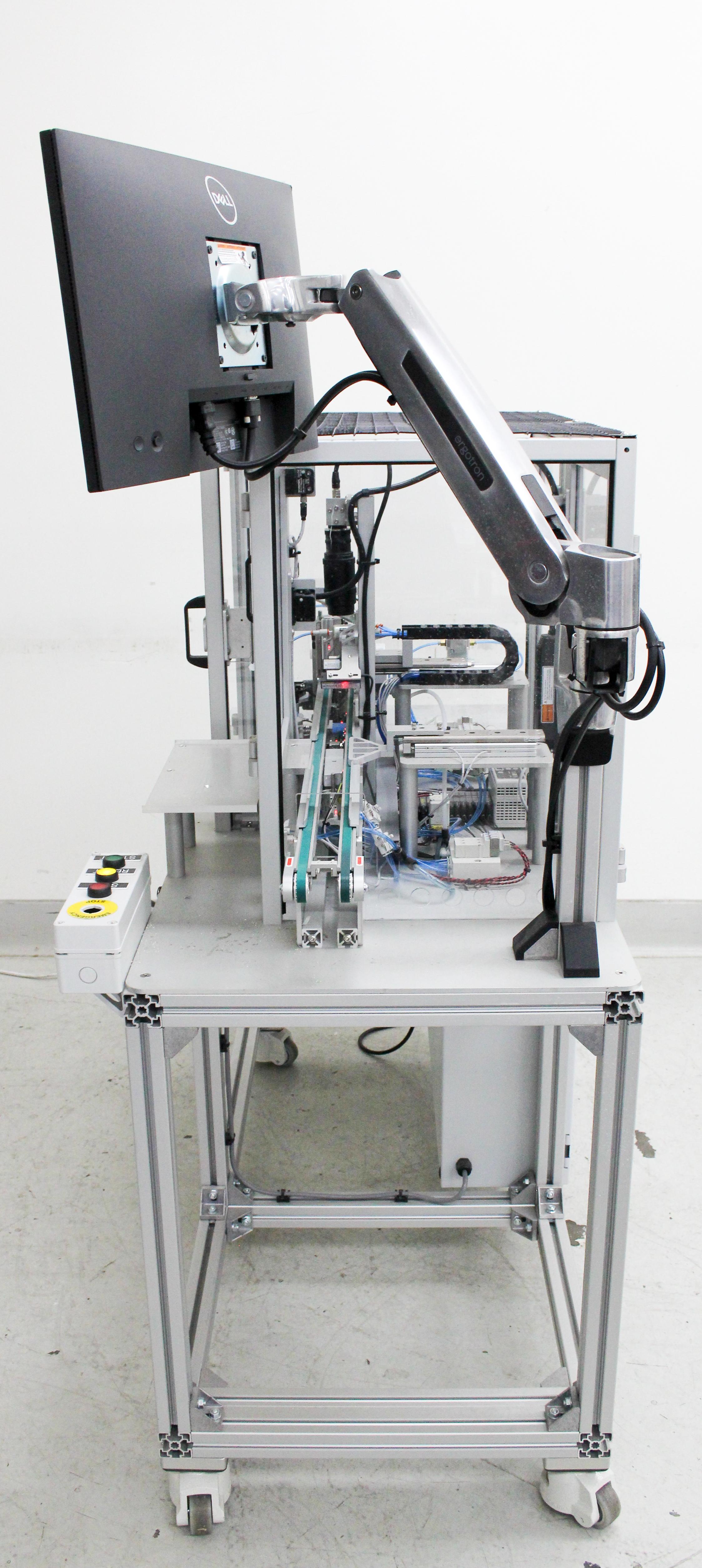

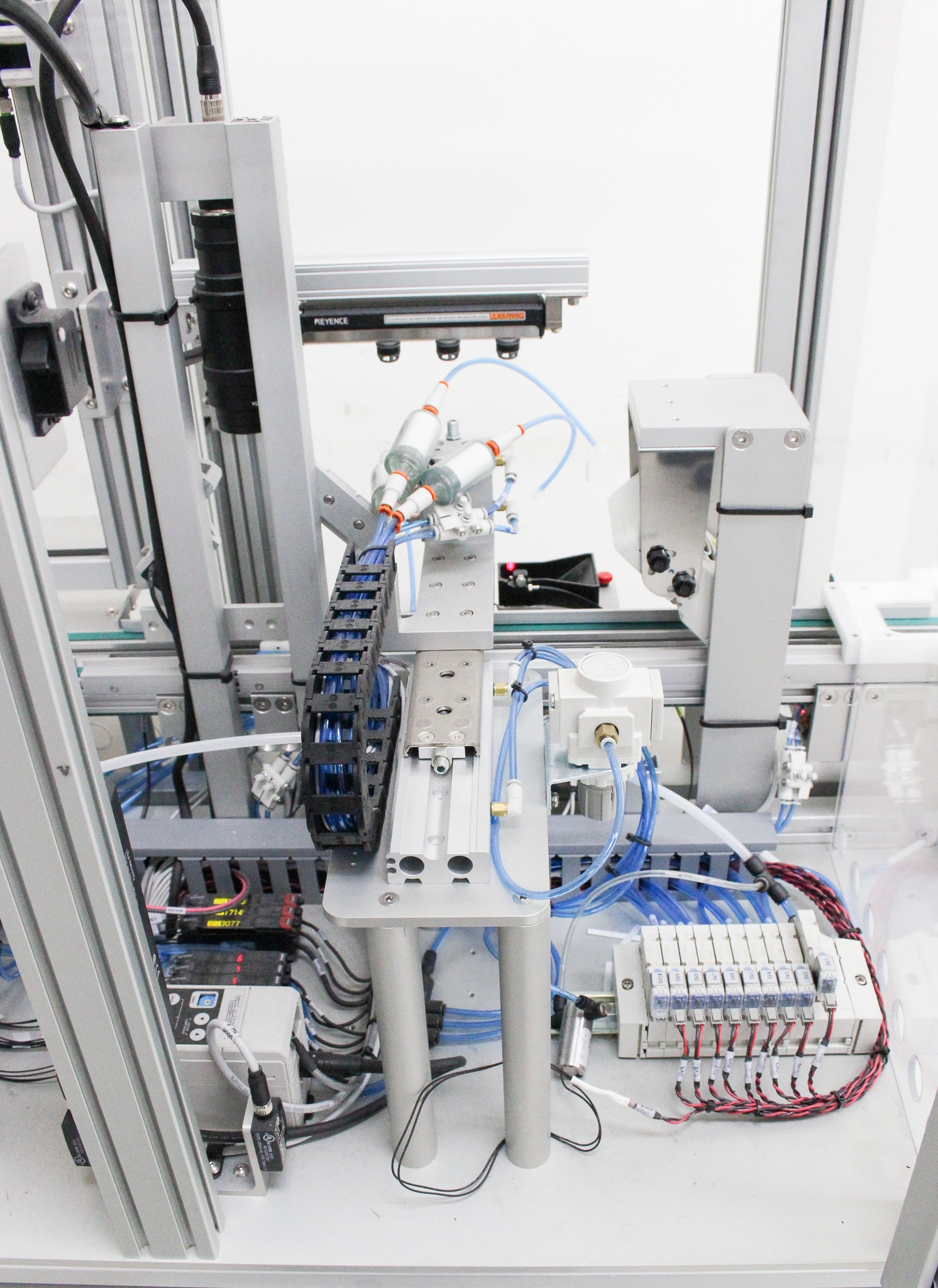

The Ridgeline Engineering Three Bead Pick and Place Model 236-001 Rev 04 is an industrial-grade automation unit designed for precision manufacturing and assembly processes. This custom machine incorporates vision inspection technology, a conveyor system, and a control panel housed within a mobile workstation. Notably, it is used for creating Accula cartridges with high efficiency and accuracy. Built by Ridgeline Engineering, specialists in industrial automation since 1990, the unit comes in fair condition with several cosmetic defects and needs repairs but is functional. Key features include its application in pick-and-place tasks for circuit board assembly and other manufacturing operations. Although the unit powers on, it has a cracked screen display and a missing kill switch, indicating further repairs might be required for optimal operation. Dimensions are approximately 27 inches in length, 60 inches in width, and 73 inches in height. The equipment uses 120V power at 50Hz/60Hz frequencies.

Key Features

- Custom pick and place machine for precise manufacturing

- Incorporates vision inspection for quality assurance

- Includes a conveyor system for automated processes

- Control panel mounted on a mobile workstation

- Utilizes 120V power for versatile industrial applications

- Functional condition with notable cosmetic defects

Specifications

- Model: 236-001 Rev 04

- Power: 120V, 50Hz/60Hz

- Condition: Fair - Needs repairs

- Functional: Yes

- Includes power cord

- Manufactured by Ridgeline Engineering, USA

- Dimensions: 27in length, 60in width, 73in height

- Weight: 330 lbs

Weight

Imperial: 396.0 Pounds

Metric: 179.62 Kilograms

Shipping Dimensions

Imperial: 32.4 lb x 72.0 lb x 87.6 lb

Metric: 82.3 cm x 182.88 cm x 222.5 cm

Harmonized Code

847989

Harmonized Code Details

847989 - Machines and mechanical appliances having individual functions, not specified or included elsewhere. This code is appropriate given the machine's custom design for specific manufacturing tasks in automation and assembly processes.

Comments 0

There are currently no public comments.