USI Prism Ultra-Coat 300 Coater In-line Selective Coating Includes Computer 220V

USI

Details

-

CategoryProduction / Manufacturing

-

Dimension49.0in x 55.0in x 64.0in

-

Serial200918000001

-

Shipping TypeFreight

-

ManufacturingDoes Not Apply

-

Voltage / Hertz220V / 50Hz/60Hz

Description

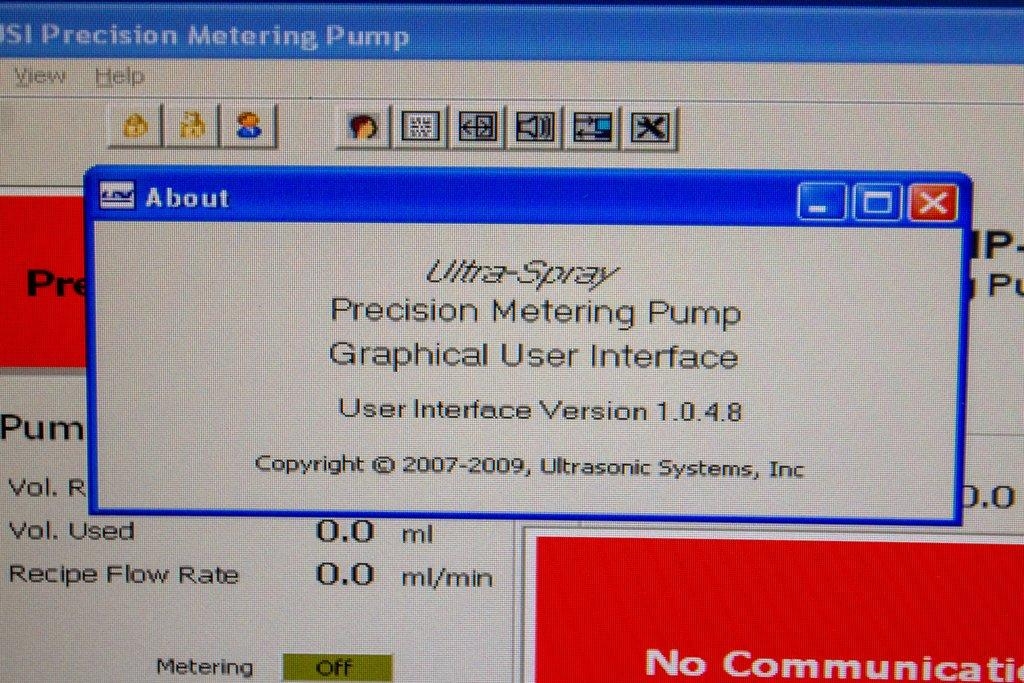

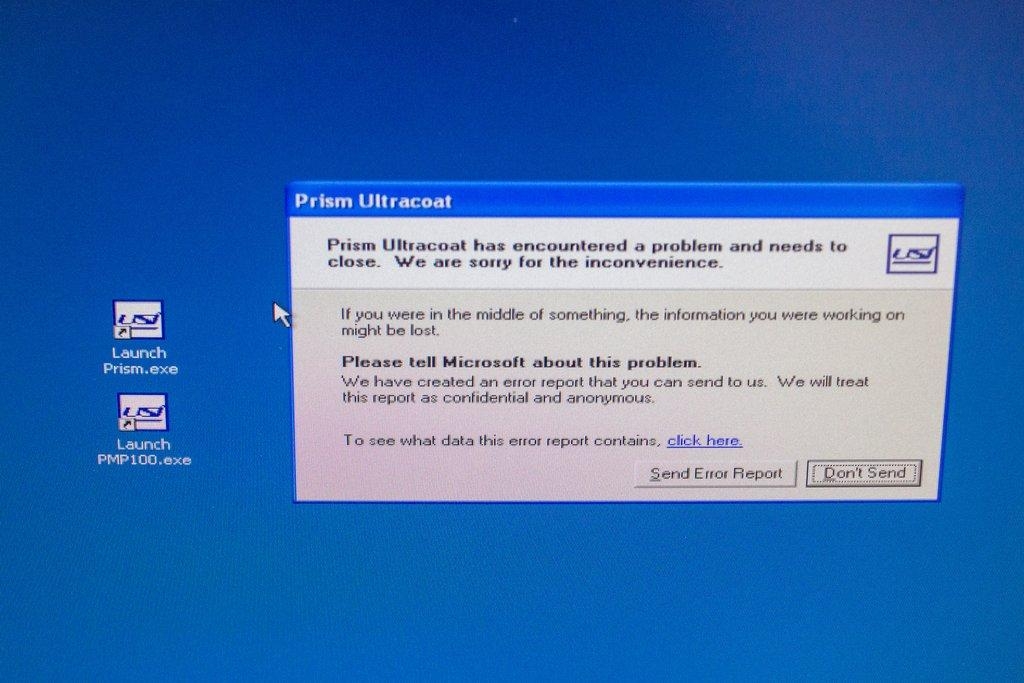

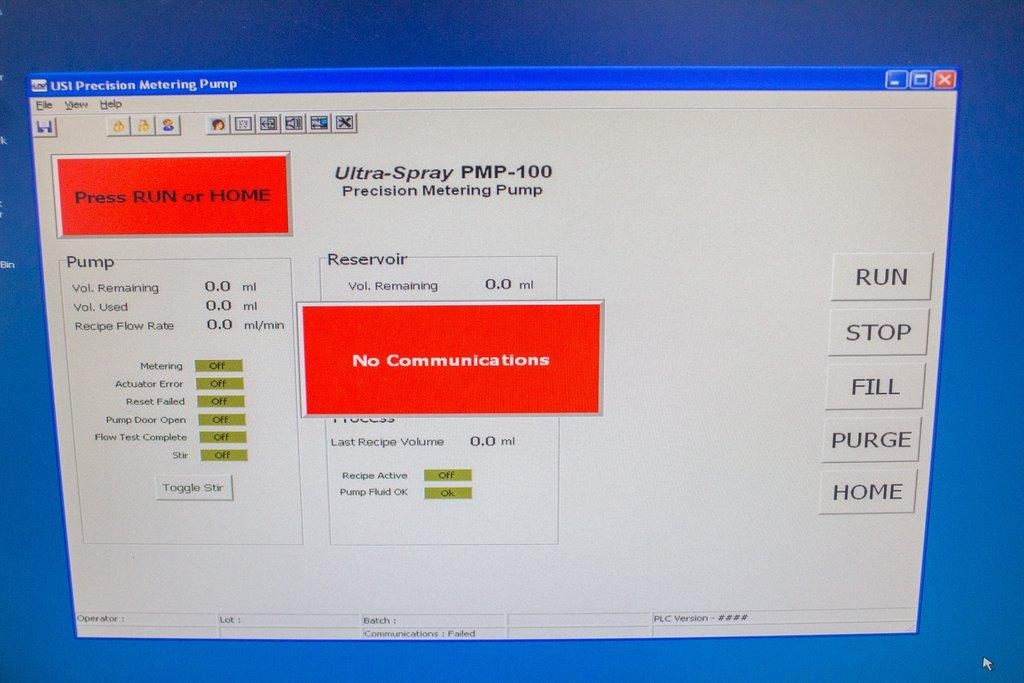

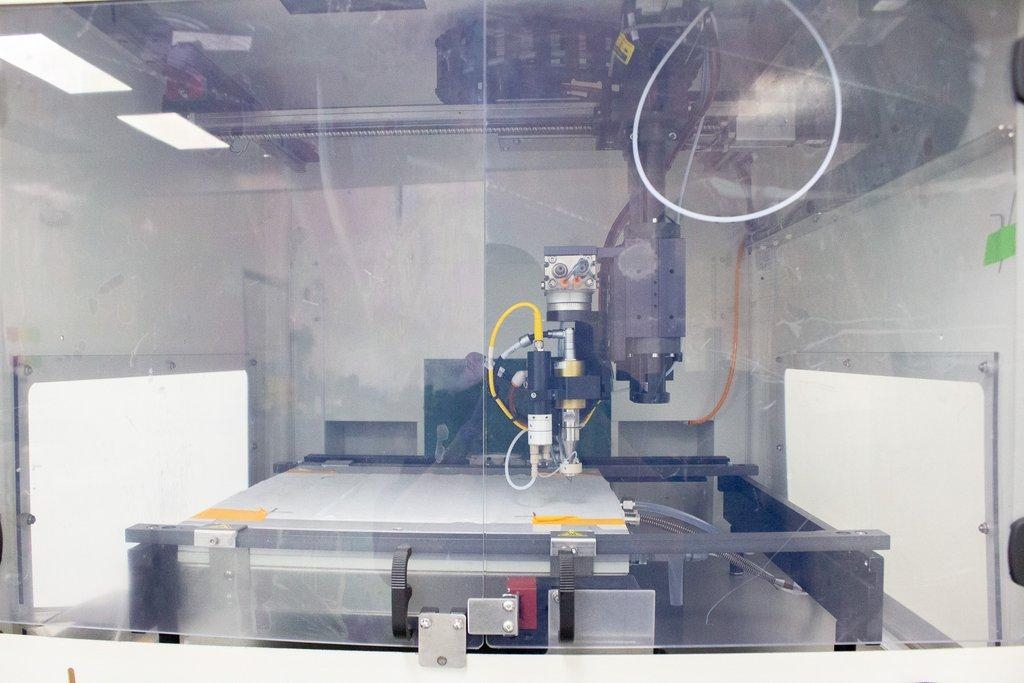

USI Prism Ultra-Coat 300 Coating System, model P300-1-250 (S/N 200918000001). Condition F Fair: unit powers on but communication to the motion and I O controllers failed, so software could not establish control. Includes the system computer with Windows based Ultra-Coat GUI and a power cord. Designed for in line selective conformal coating of PCBs and other substrates, the PRISM platform uses USI’s nozzle less ultrasonic Ultra Spray and T CAT technology to produce super thin, uniform, rectilinear films with minimal waste. Configurable with up to two coating heads on a single gantry, supporting ILDS dual mode and Blade heads. The X Y Z theta phi gantry employs ball screw actuators with servo motors on X and Y, and stepper driven theta. Precision Metering Pump delivery uses micro stepping for repeatable flow, with options for dual PMP, recirculation, and mixing. Ethernet based controls, recipe programming, SMEMA in line capability, and batch or manual conveyor modes. 220V, 50 60 Hz. 30 day parts warranty.

Key Features

- Nozzle-less ultrasonic Ultra-Spray for thin, uniform, defect-free coatings

- T-CAT thin coating application technology with programmable motion control

- Configurable gantry with up to two coating heads on a single carriage

- Supports ILDS dual-mode head (narrow and wide) and Blade head for large areas

- X-Y-Z-theta-phi motion platform; ball screw actuators and servo motors on X and Y

- Precision Metering Pump liquid delivery with micro-stepping drive for accurate flow

- Windows-based Ultra-Coat GUI with Ethernet-based motion and I/O control

- Recipe programming for lines, fills, circles, dots, and repeat up to 999 times

- Batch, manual conveyor, and in-line SMEMA operation modes

- Safety-rated viewing panels, limit switches, and high-flex energy-chain cabling

- Includes system computer and power cord

- 220V, 50/60 Hz; Country of Origin: United States; 30-day parts warranty

Specifications

- Make and Model: USI Prism Ultra-Coat 300 Coating System, Sub-model P300-1-250

- Serial Number: 200918000001

- Condition: F Fair; powers on; communication with controllers failed; unable to control via software

- Included: System computer with Ultra-Coat GUI; power cord; no service records or manuals

- Coating Technology: Nozzle-less ultrasonic Ultra-Spray for super-thin, rectilinear patterns

- Heads Supported: ILDS dual-mode (narrow/wide) and Blade head for wide coverage

- Liquid Delivery: Precision Metering Pump (positive displacement); micro-stepping drive control

- Flow Management: Options for dual PMP, continuous flow, recirculation, mixing, and automatic stirring

- Motion Platform: X-Y-Z-theta-phi gantry; ball screw actuators; brushless servo motors on X/Y; stepper-driven theta

- Controls: Ethernet-based motion and I/O; Windows system controller; 17 inch monitor, keyboard, mouse

- Software Functions: Manual controls; teach with laser pointer or camera; spreadsheet recipe editor

- Recipe Capabilities: COAT, FILL, CCFILL, circles, dots, trim to circle, WAIT, CLEAN, REPEAT up to 999 cycles

- Operation Modes: Batch loading, manual conveyor, and in-line conveyor with SMEMA protocol

- Safety and Build: Heavy-duty welded steel frame; safety glass panels; IP67 work light; home and limit switches

- Applications: Selective conformal coating for PCBs, electronics, semiconductors, medical devices, fuel cells, solar, glass displays

- Electrical: 220V, 50/60 Hz

- Warranty: 30-day warranty on part

- Country of Origin: United States

- Actual Dimensions: 49 x 55 x 64 in (L x W x H)

- Actual Weight: 900 lb; Shipping Weight: 1080 lb; Packed size approx. 58.8 x 66.0 x 76.8 in

Weight

Imperial: 1080.0 Pounds

Metric: 489.88 Kilograms

Shipping Dimensions

Imperial: 58.8 lb x 66.0 lb x 76.8 lb

Metric: 149.35 cm x 167.64 cm x 195.07 cm

Harmonized Code

842489

Harmonized Code Details

8424.89 Mechanical appliances for projecting, dispersing or spraying liquids or powders, other. This system is an industrial ultrasonic spray coating machine used to apply liquid coatings to substrates.

Comments 0

There are currently no public comments.