YES YES-EcoCoat 1224P Coater Deposition System New Includes Computer

YES

Details

-

CategoryProduction / Manufacturing

-

Dimension57.0in x 72.0in x 62.0in

-

Serial90222

-

Shipping TypeFreight

-

ManufacturingDoes Not Apply

-

Voltage / Hertz208V / 50Hz/60Hz

Description

The Yield Engineering Systems YES-EcoCoat US 1224P is a silane monolayer vapor phase deposition system tailored for modern laboratory needs. It features an adjustable, large-capacity chamber, suitable for process development and production. With operational temperatures ranging from ambient up to 205°C and excellent thermal uniformity, the system ensures consistent silane deposition on various substrates such as wafers, glass, and thermoplastics. Equipped with three independent vapor delivery lines and in-situ plasma, this system adapts to numerous applications, including surface modification, anti-stiction films, and biomolecule bonding. Its plasma cleaning capability ensures that surfaces are hydrophobicity-controlled, preparing substrates for optimal silane coating. Included new peripherals enhance the system's functionality, making it ready for both research and industrial-scale applications.

Technician comment

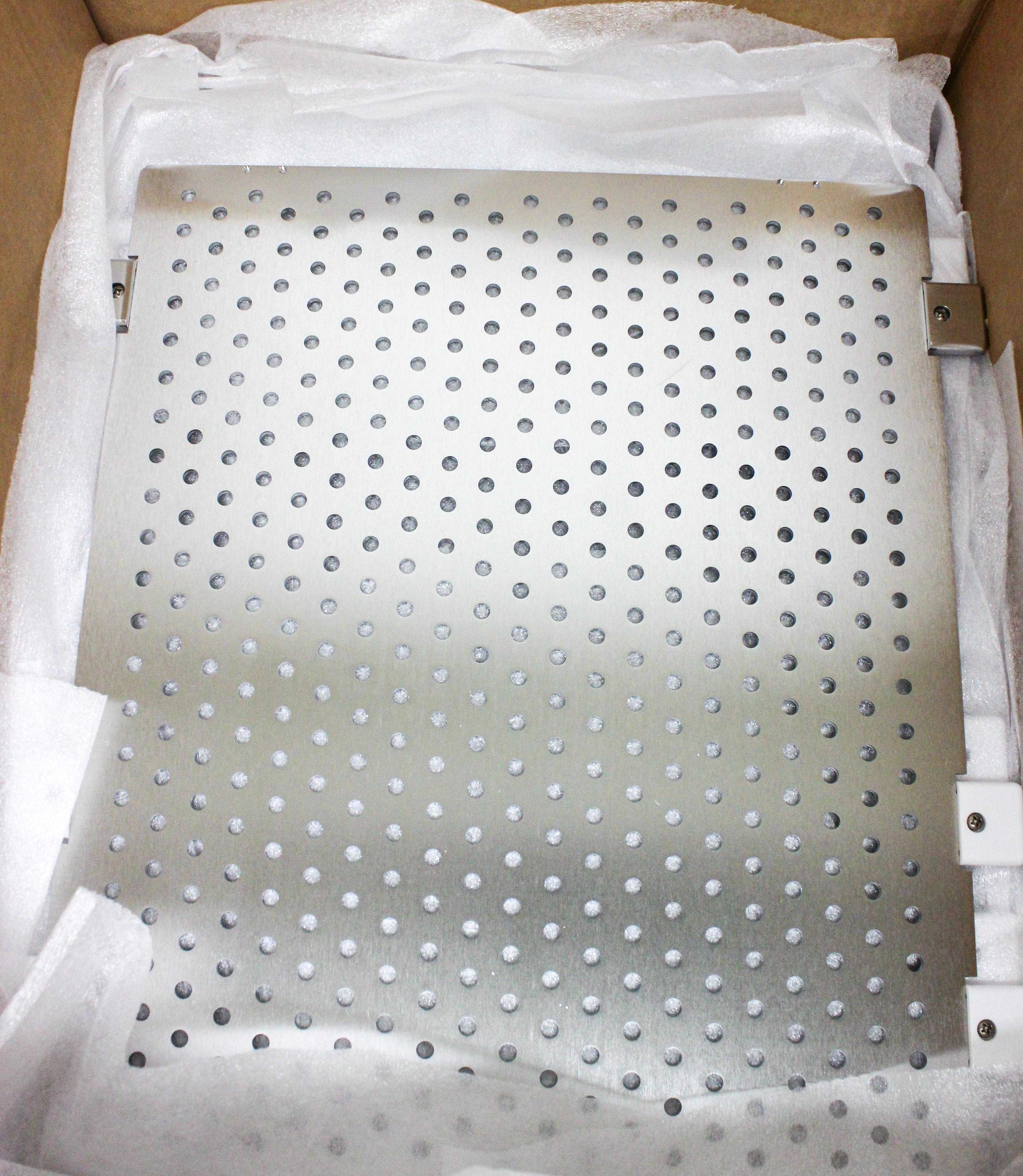

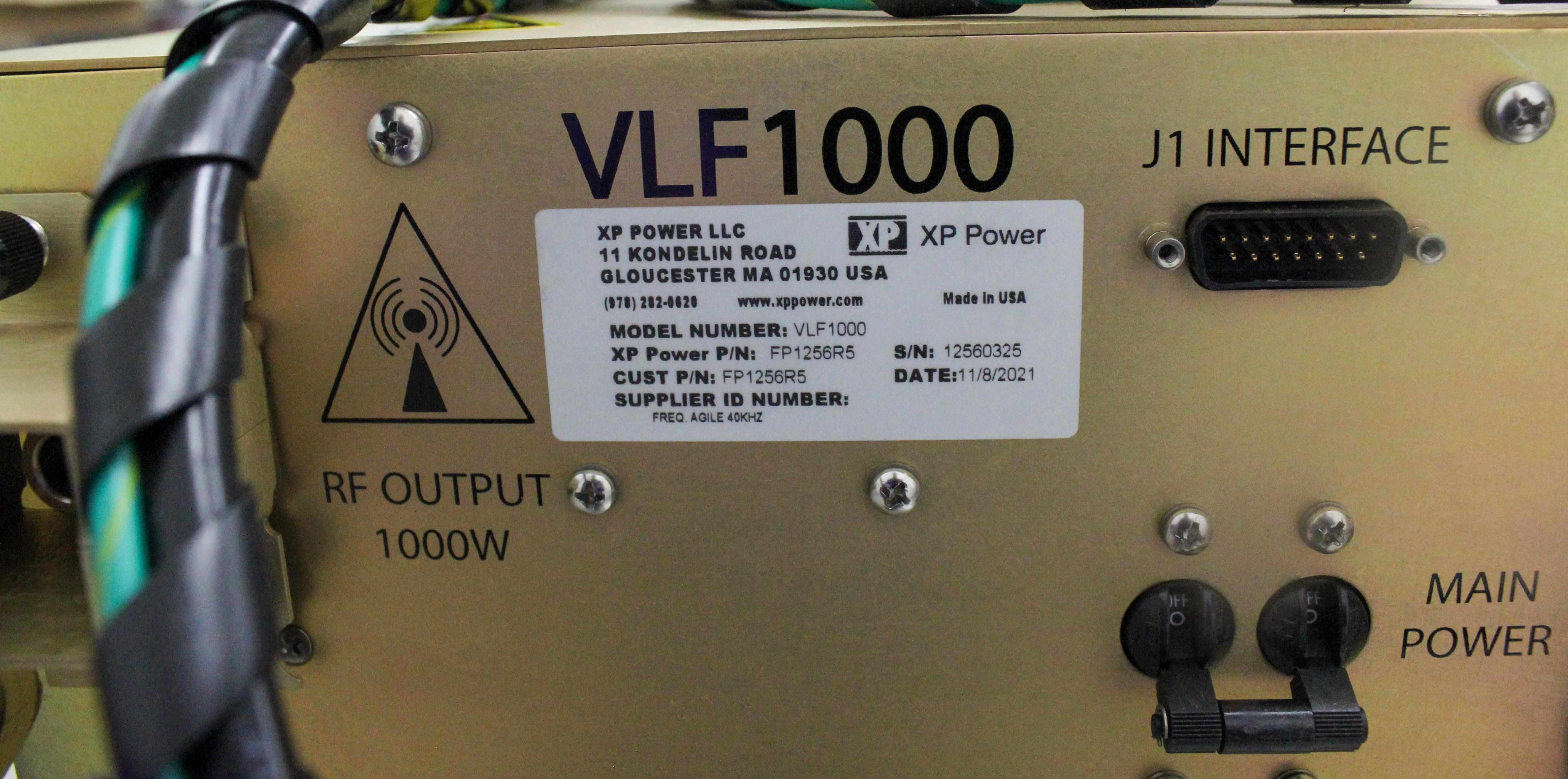

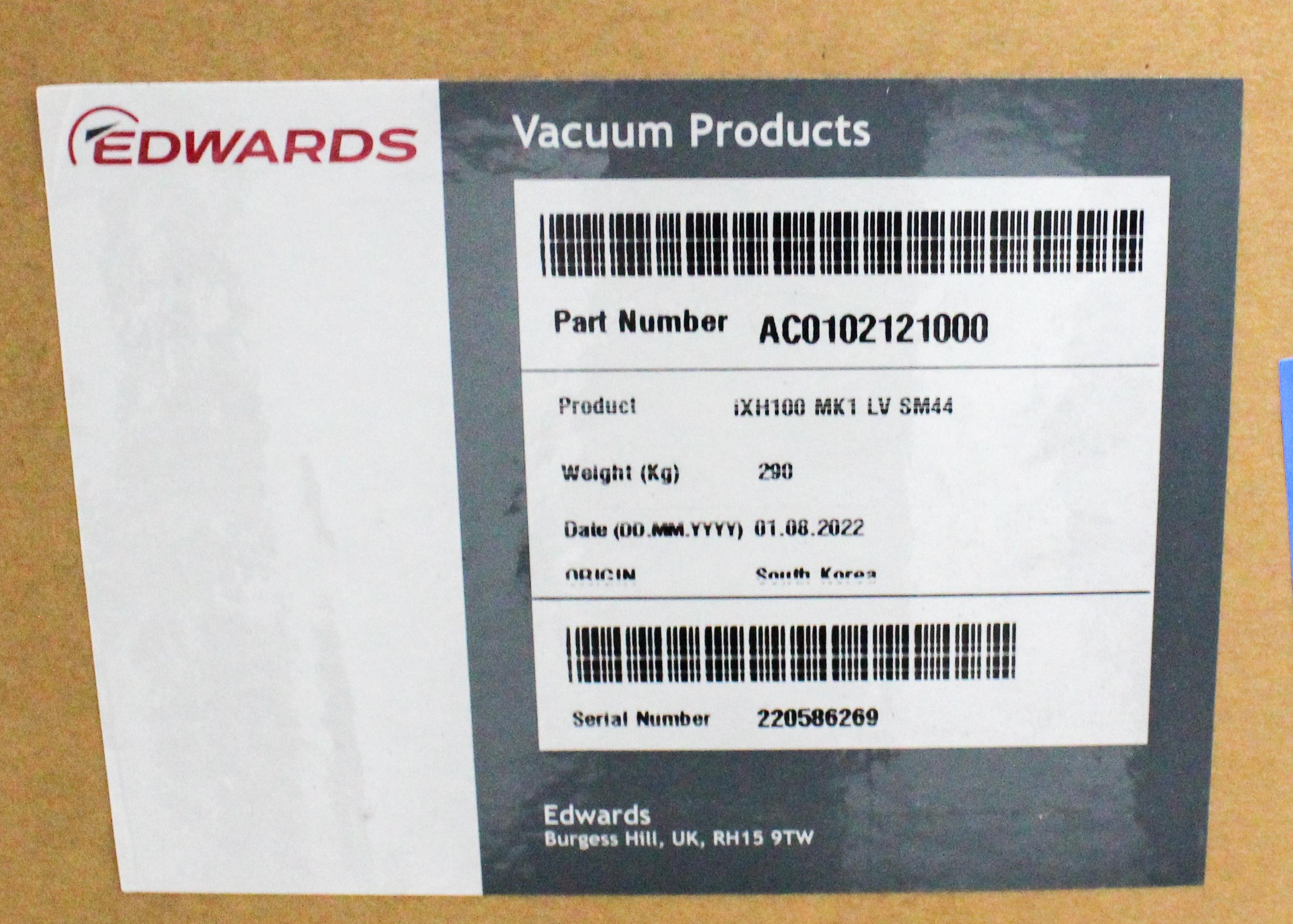

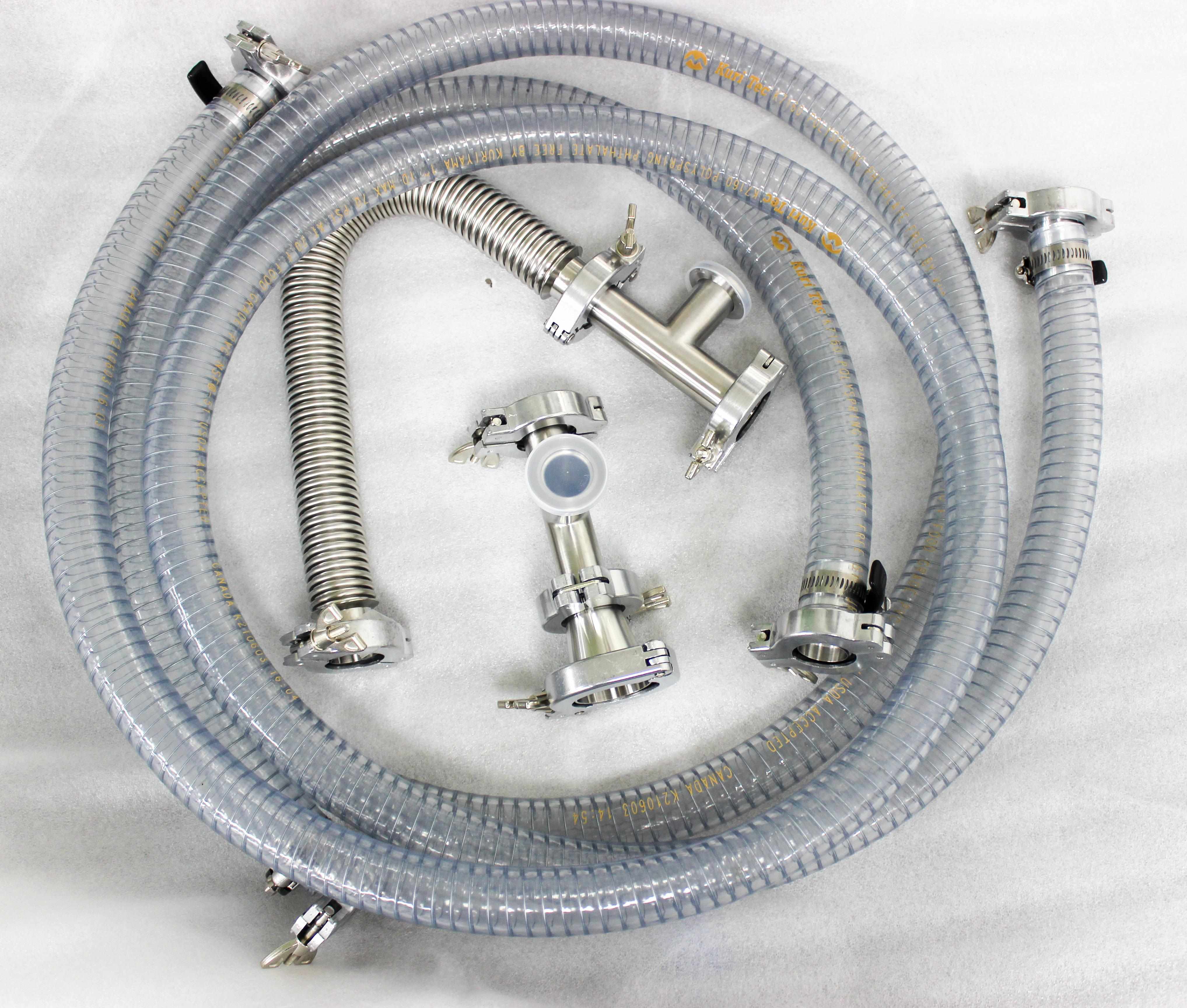

This Ecocoat unit is brand new and the custom system includes the following brand new peripherals: - YES Rolling System Cart for EcoCoat, 47w x 47d x 26h - HP ProDesk PC with Intel I5, and HP z24f G3 Monitor -YES Data Acquisition Software - Pump (iXH100/Edwards ES602 Silencer) Item No. A5058800 - SMC Thermo Chiller HRS012-AN-20 - MV Vapor Multi-Trap Chiller Model 355040S - YES/XP Power VLF-1000 - MFC 100SCCM 02 - Miller Electric Coolmate 3 Cooler, Sku 043008 - Bottle Glass Septum Pierce 40ML x 12 - Quick Kit 50ML 1/8 Omni - Additional accessories (see photos)

Key Features

- Silane monolayer vapor phase deposition

- In-situ plasma cleaning

- Ambient to 205°C operation temperature

- Three independent vapor delivery lines

- Configurable large capacity chamber

- Suitable for process development and volume production

- Includes computer with data software

Specifications

- RF Plasma Frequency / Power: 40 kHz, 100-1000 Watts

- Operational Temperature: Ambient to 205°C

- Temperature Uniformity: ± 1.5% after stabilization

- Chamber Pressure Control: 100 mT - 100 T

- Chemical Usage: 0.1 – 3.0 mL (typical process)

- Chemical Dispense Volume: Increments of 0.1 mL

- Vapor Delivery Lines: Three, with independent process and thermal control

- Chamber Material: 316L stainless steel

- Chamber Size: 40.6 cm (W) x 46 cm (D) x 40.6 cm (H)

Weight

Imperial: 1320.0 Pounds

Metric: 598.74 Kilograms

Shipping Dimensions

Imperial: 68.4 lb x 86.4 lb x 74.4 lb

Metric: 173.74 cm x 219.46 cm x 188.98 cm

Harmonized Code

8421.99.00

Harmonized Code Details

8421.99.00 - Parts of machinery and apparatus for filtering or purifying gases. This code applies as the equipment functions as a deposition system and includes components that handle gas delivery and filtration.

Comments 0

There are currently no public comments.